Passages in Black are found in all editions of the Manual. Those in red only appear in the ’60 edition. If starred in red the passage is not included in the ’60 edition.

This comparison project of the ’60 and 66′ editions is currently a work in progress.

ORDNANCE INSTRUCTIONS

FOR THE

UNITED STATES NAVY.

1866.

PART I.

RELATING TO THE

PREPARATION OF VESSELS OF WAR FOR BATTLE,

AND TO THE

DUTIES OF OFFICERS AND OTHERS WHEN AT QUARTERS.

PART II.

THE EQUIPMENT AND MANŒUVRE OF BOATS

AND

EXERCISE OF BOAT HOWITZERS.

PART III.

ORDNANCE AND ORDNANCE STORES.

FOURTH EDITION.—PUBLISHED BY ORDER OF THE NAVY DEPARTMENT.

WASHINGTON:

GOVERNMENT PRINTING OFFICE,

1866.

Ordnance any suggestions relative to future additions or

corrections, with the reasons for any proposed changes,

quoting part, page, and paragraph by its number.

CONTENTS.

[A full index will be found at the end of the book.]

| PART | PAGE | |

| Captain | 1 | 3-6 |

| Executive Officer | 1 | 6, 7 |

| Officers in charge of divisions | 1 | 8, 9 |

| Master | 1 | 9 |

| Chief Engineer | 1 | 9 |

| Gunner | 1 | 9-12 |

| Carpenter | 1 | 12 |

| Yeoman | 1 | 13 |

| General distribution of officers and men at quarters | 1 | 14-20 |

| Distribution and arms of men at the guns | 1 | 21-25 |

| Duties at quarters in battle or exercise | 1 | 26-40 |

| Equipments and Implements | 1 | 33-35 |

| Broadside guns, stations and gun-numbers | 1 | 35 |

| Calls for assembling at quarters | 1 | 36, 37 |

| Preparations for exercise at general quarters | 1 | 38-40 |

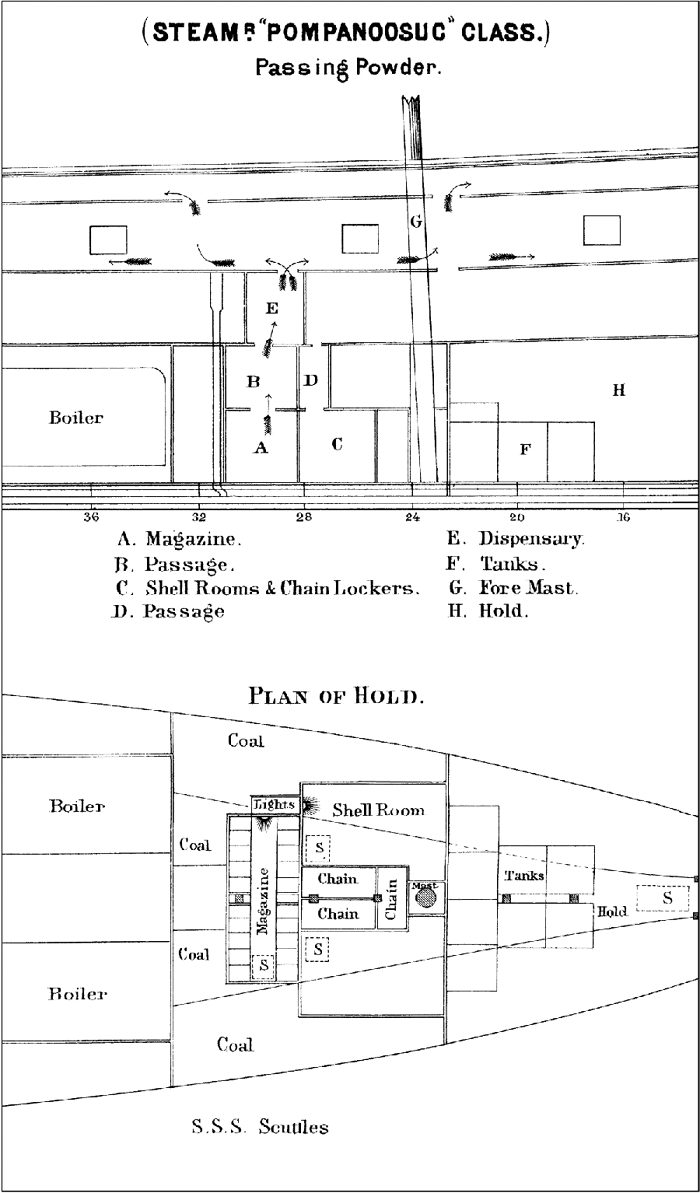

| Arrangements for delivering and distributing powder | 1 | 41-45 |

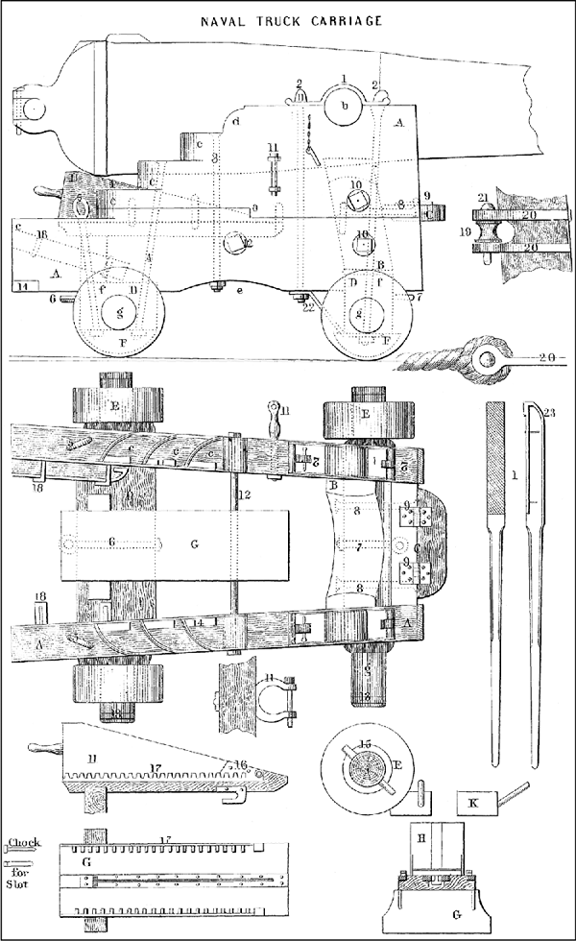

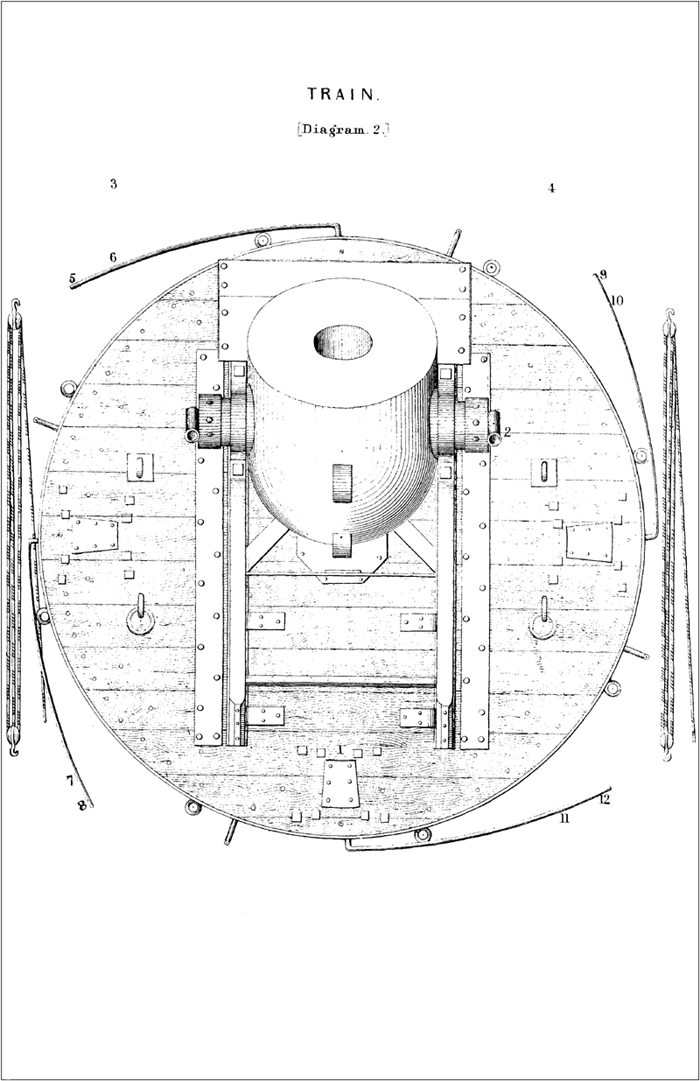

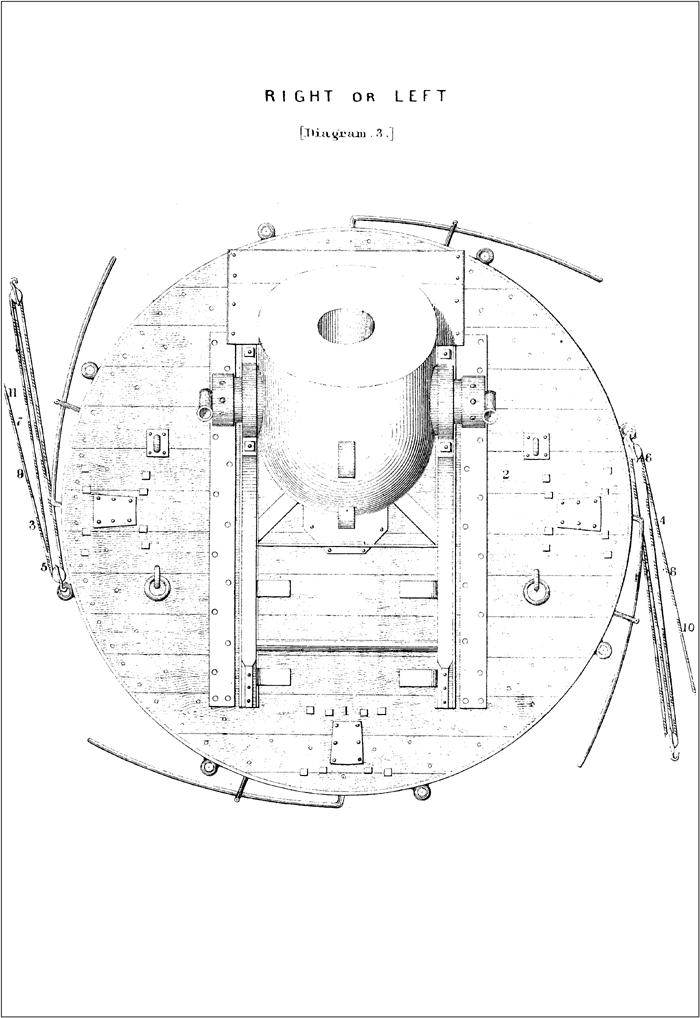

| Naval gun-carriages | 1 | 45 |

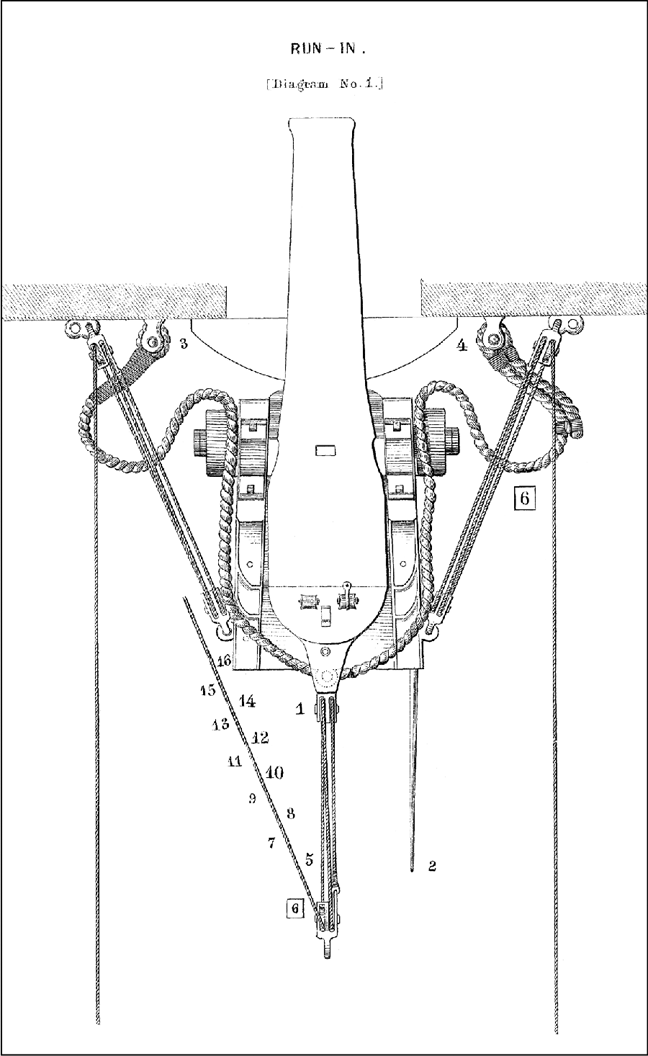

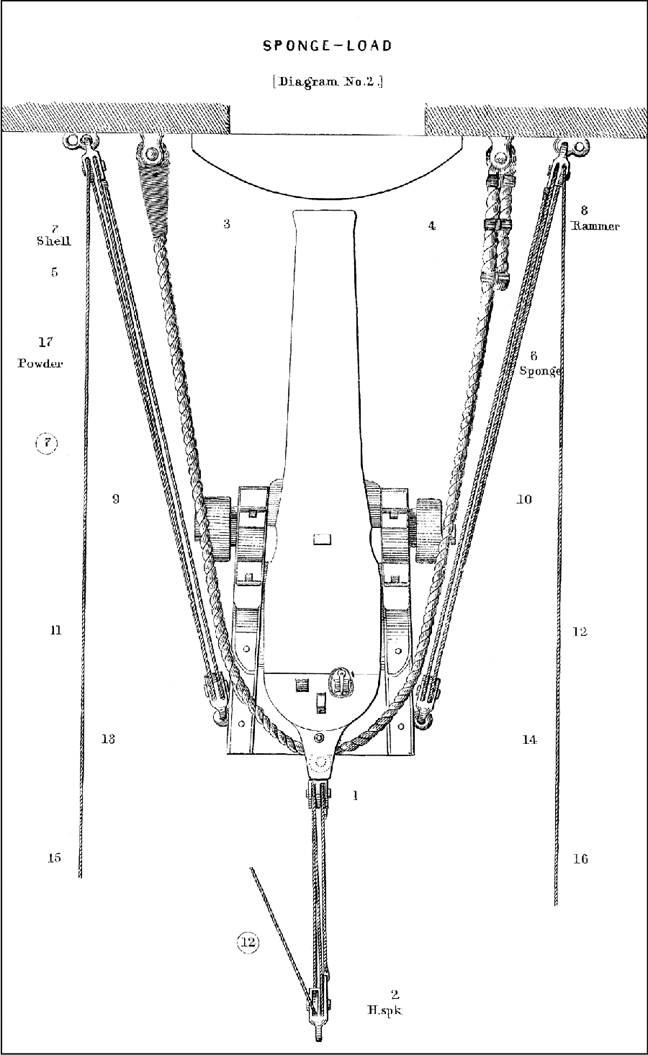

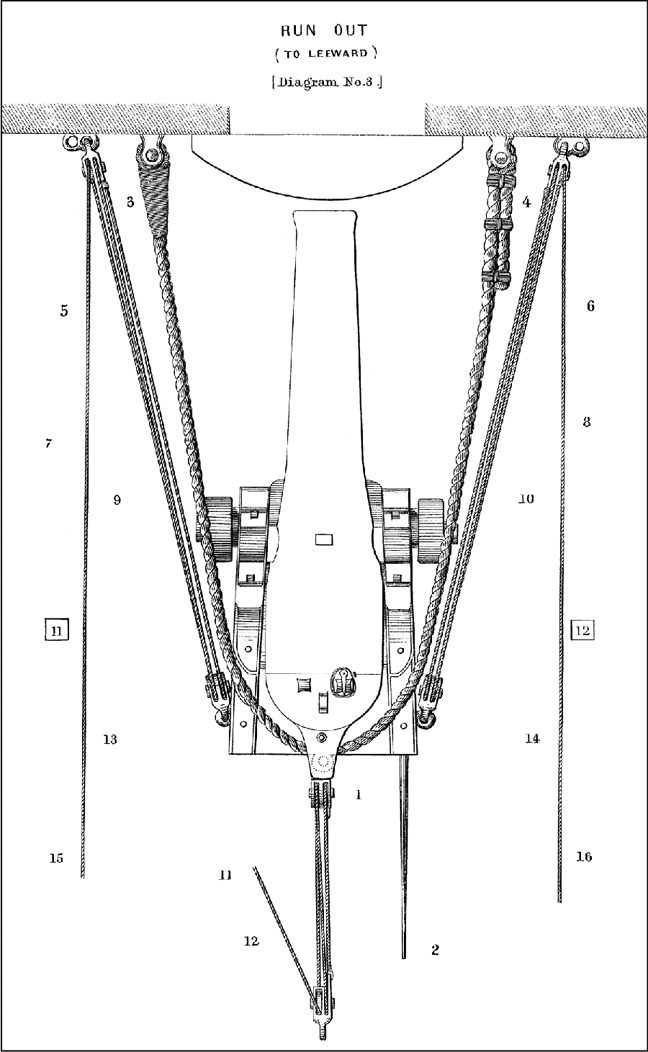

| Exercise of broadside-guns | 1 | 46-60 |

| Exercise of pivot-guns | 1 | 61-73 |

| Notes upon the manual exercise | 1 | 74-88 |

| The use of fuzes | 1 | 89-91 |

| Boarders | 1 | 92, 93 |

| General precautions to be observed in time of war | 1 | 94-96 |

| Directions in case of fire | 1 | 97-100 |

| Rifled Cannon | 1 | 101-107 |

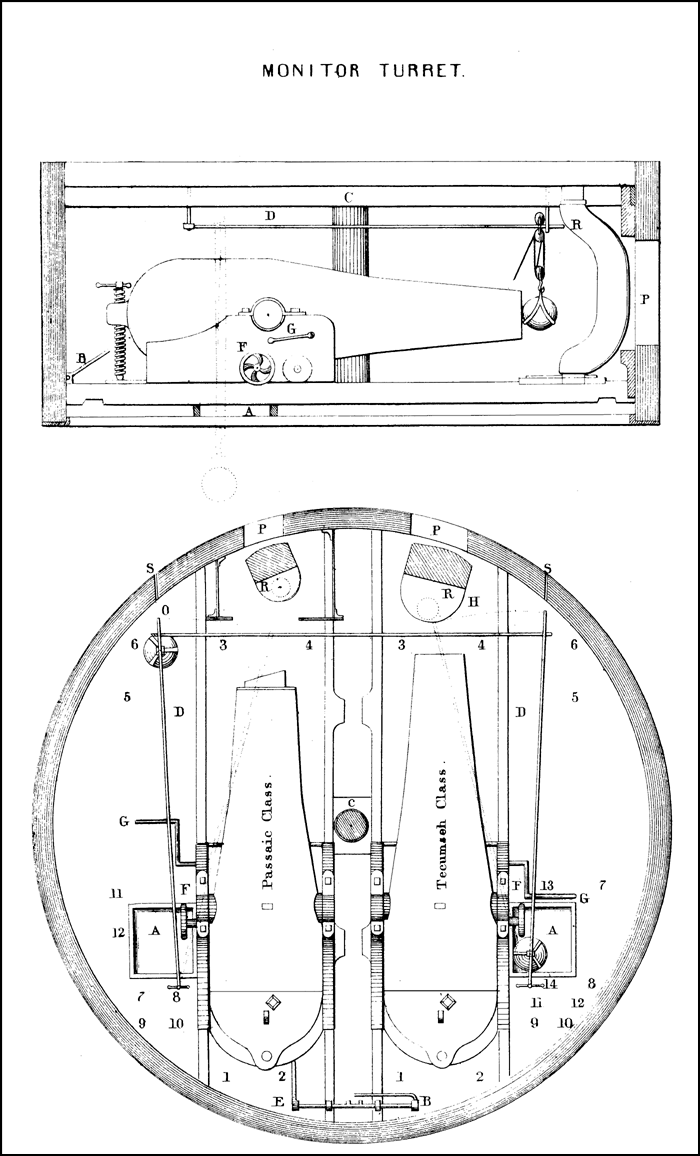

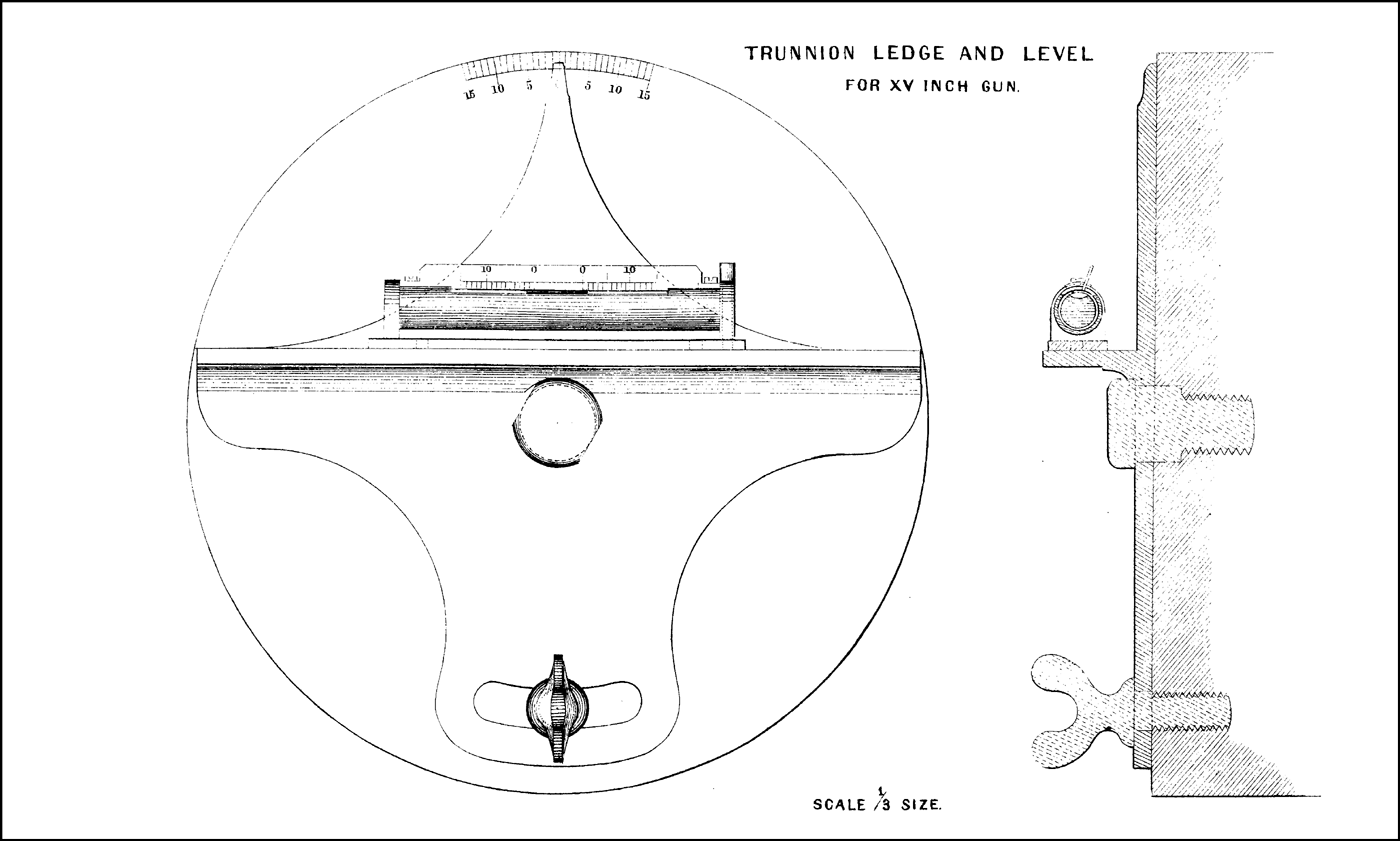

| Monitors | 1 | 108-112 |

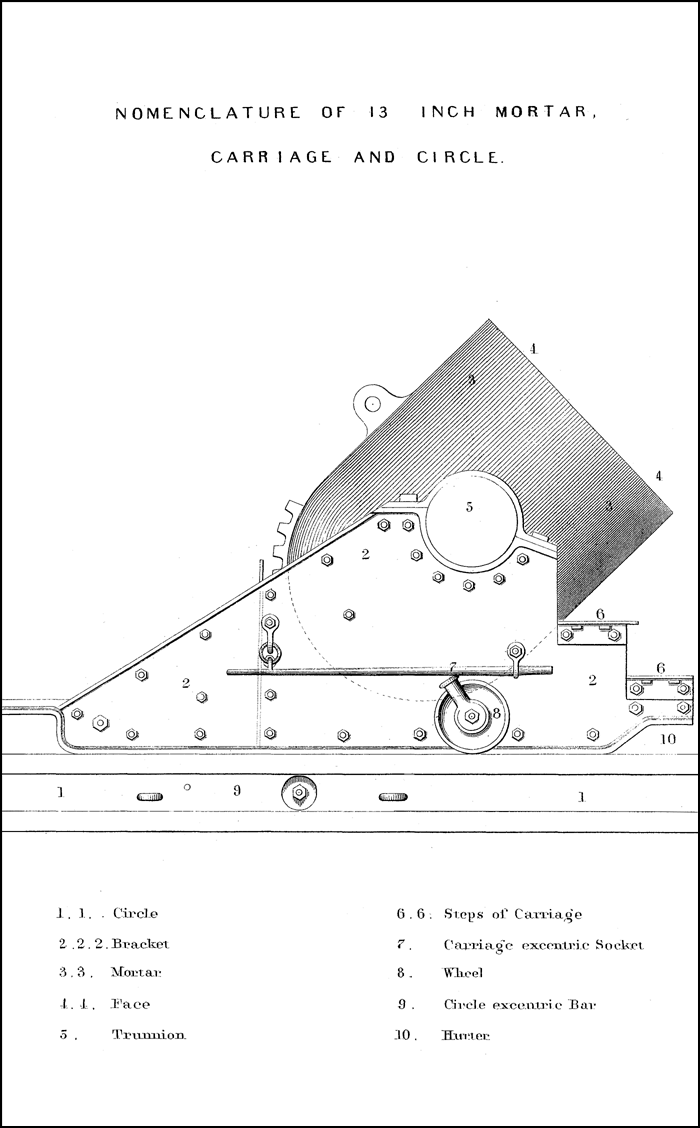

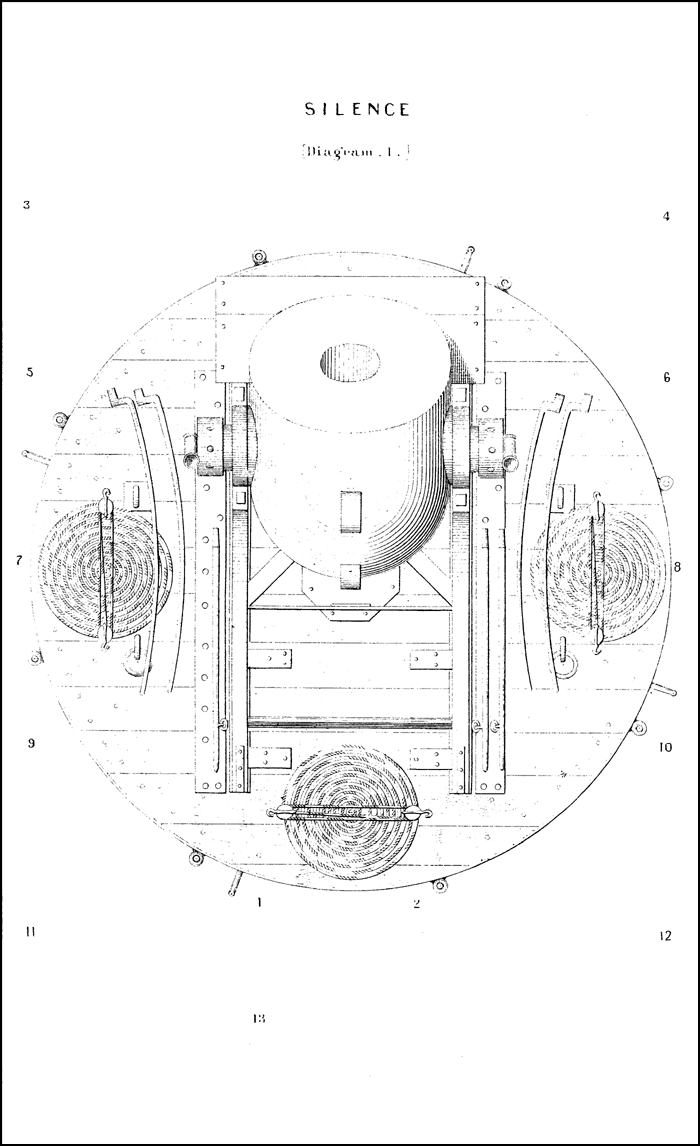

| Mortars | 1 | 113-127 |

| Miscellaneous Operations | 1 | 128-131 |

| Equipment of boats | 2 | 3-9 |

| Fixtures in boats for boat-guns | 2 | 6-9 |

| Exercise and Manœuvre for boat-howitzers | 2 | 10-18 |

| Exercise with howitzer on field-carriage | 2 | 19, 20 |

| Remarks on the use of Naval Light Artillery | 2 | 21, 22 |

| Notes on the use of boat-howitzers | 2 | 22-24 |

| Manœuvres of boats armed for service | 2 | 24 |

| Landing seamen, marines, and howitzers | 2 | 25-27 |

| Ordnance and Ordnance Stores | 3 | 3-80 |

| Inspection and Proof of Naval guns | 3 | 8-17 |

| Use of the Inspecting Instruments | 3 | 18-21 |

| Powder-Proof | 3 | 22 |

| Water-Proof | 3 | 23 |

| Marking guns | 3 | 23 |

| Extreme proof of trial guns | 3 | 24-26 |

| Preparation of guns for service | 3 | 27-29 |

| Preservation of guns | 3 | 30-32 |

| Examination of guns | 3 | 33-35 |

| Inspection of shot and shells | 3 | 36-38 |

| Shot and shell gauges | 3 | 39, 40 |

| Piling of balls | 3 | 41, 42 |

| Preservation of shot and empty shells | 3 | 43 |

| Preparation of shell for service | 3 | 44-47 |

| Gunpowder | 3 | 48-55 |

| Preservation and storage of powder | 3 | 48-53 |

| Service-charges for naval guns | 3 | 53, 54 |

| Boxes for small-arm ammunition | 3 | 55, 56 |

| Cannon and Friction primers | 3 | 56, 57 |

| Cartridge-bags | 3 | 57-59 |

| Magazines and shell rooms | 3 | 60-64 |

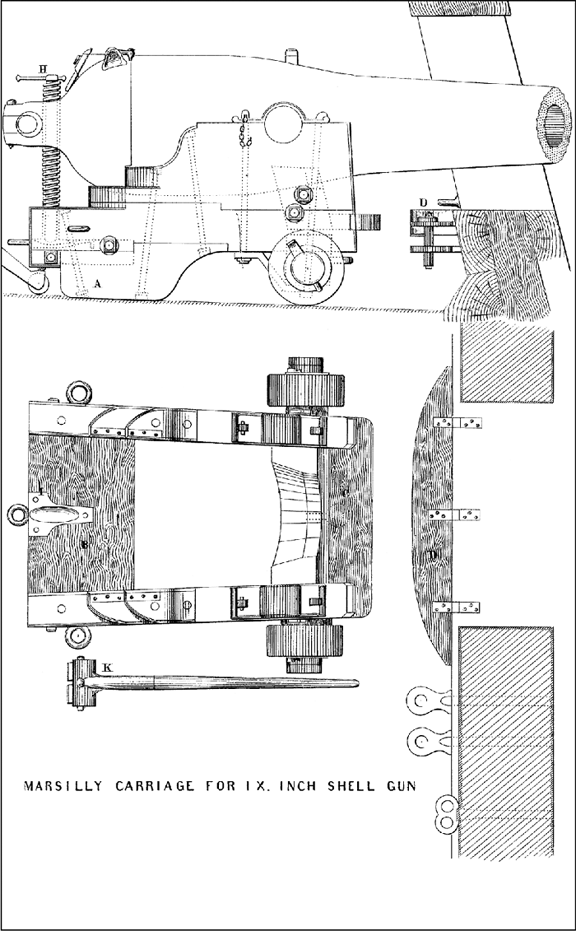

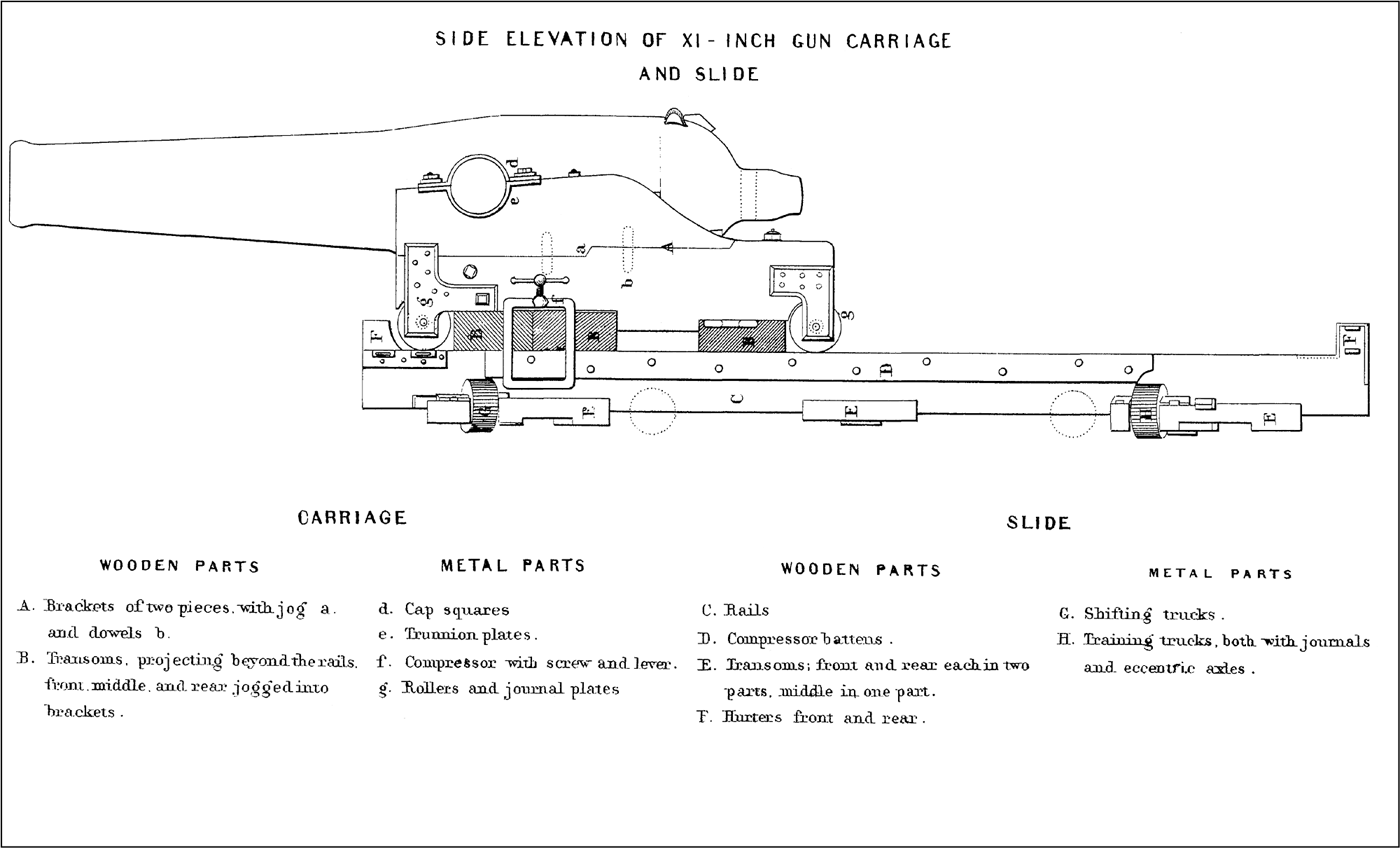

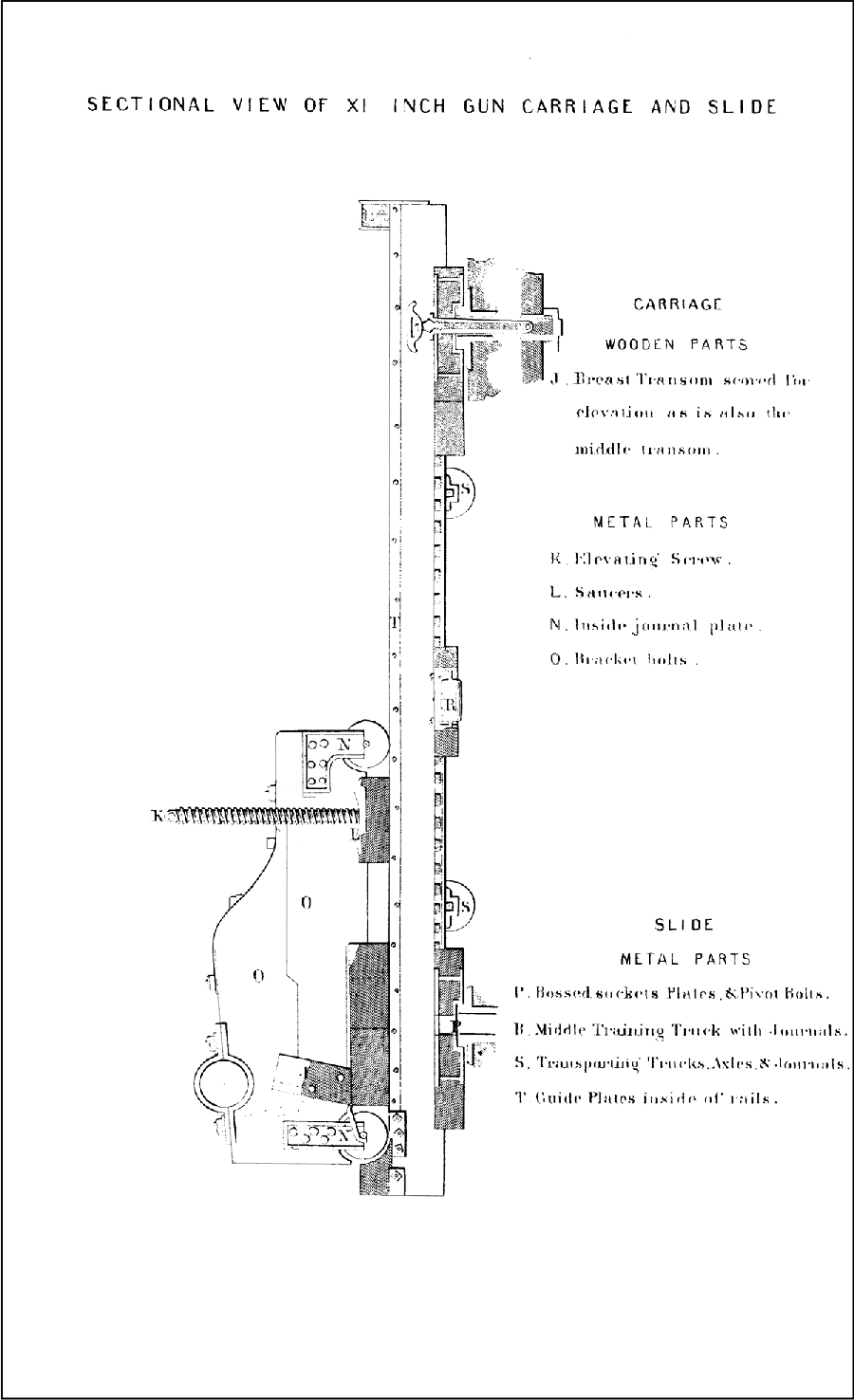

| Gun-carriages | 3 | 65, 66 |

| Gun-gear | 3 | 66, 67 |

| Griolet | 3 | 68 |

| Directions for cleaning arms | 3 | 80-82 |

| Paints and Lacquers | 3 | 83-89 |

| APPENDIX. | ||

| Directions as to using the allowance tables of crews | A | iii-v |

| Table I. Showing the number of hands for various kinds of guns |

A | vi |

| Table II. Allowance of Petty Officers for various kinds of vessels |

A | vii, viii |

| Table III. Allowance of Officers, when | A | ix |

| Table IV. Allowance of Marines, when | A | x |

| Graduation of sights and ranges, of 32 pds.: of 27 or 33 cwt.: No. 1 |

B | xi |

| Graduation of sights and ranges, 32 pds.: of 42 or 57 cwt.: No. 2 |

B | xii |

| Graduation of sights and ranges, 8 in.: of 55 or 63 cwt.: No. 3 |

B | xiii |

| Graduation of sights and ranges, 9 and 11 in. shell guns, No. 4 |

B | xiv |

| Approximate ranges of Shell guns No. 5 | B | xv |

| Approximate ranges of Shot guns and howitzers No. 6 | B | xvi |

| Approximate ranges of Rifle guns No. 7 | B | xvii |

| Table for finding the distance of an object at sea No. 8 |

B | xviii |

| Form of Report of Target Practice with great guns No. 9. |

B | xx, xxi |

| Form of Report of Target Practice with small arms No. 9. |

B | xxii |

| Directions as to preparing Reports of Target Practice No. 10 |

B | xxiii |

| Form of Reports of Inspection No. 1 | C | xxiv-xxvi |

| Questions to be embraced in Reports of Target Practice No. 2 |

C | xxvii |

| Tables of Allowances of Ordnance Equipments and Stores |

D | xxviii-li |

PART I.

RELATING TO THE

PREPARATION OF VESSELS OF WAR FOR BATTLE.

Bureau of Ordnance, }

Navy Department. January 1st, 1866. }

Sir:—

The Ordnance Instructions for the Navy having been again

carefully revised, and such additions and corrections made

as the new armaments of vessels of the Navy rendered

necessary, they are approved by the Bureau, and I have the

honor to submit them for the adoption of the Navy

Department.

I am, Sir, with high respect,

Your obedient servant,

H. A. WISE, U.S.N.,

Chief of Bureau.

Navy Department, }

Washington, January 1st, 1866. }

Sir:—

The revised Ordnance Instructions for the Navy, submitted

with your letter of this date, are hereby approved and

adopted by the Department, and all officers of the Navy will

strictly observe and enforce them.

Very respectfully,

GIDEON WELLES,

Secretary of the Navy.

Commander H. A. WISE, U.S.N.

Chief of Bureau of Ordnance.

CHAPTER I.

GENERAL DUTIES OF OFFICERS

IN RELATION TO ORDNANCE AND GUNNERY, AND TO MILITARY EQUIPMENTS AND

EXERCISES.

CAPTAIN.

1. The Captain or Commanding Officer will be careful to require that

all the Ordnance Instructions are strictly enforced on board the

vessel under his command; and although particular duties are assigned,

and various instructions given to the other officers of the vessel,

yet he is to see that the duties are performed, and the instructions

obeyed, by the officers to whom they are respectively addressed.

2. As soon as the crew is received on board the vessel, he shall cause

a fire-bill to be prepared, the crew shown their stations, and see

that they are duly stationed at quarters for battle (See Articles 78

to 103), and exercised at general quarters, and by divisions,

particularly the powder division (See Articles 180 to 201), until

each officer and man is thoroughly instructed in his duties; after

which the exercises are to be frequent during the cruise. Exercises

which are short and spirited are preferable to those which are long

and fatiguing. Distinctions and indulgences to those who excel are

recommended.

When the men have become well acquainted with their duties at the

guns, and in passing powder, or when the general duties of the ship

are unusually fatiguing, the divisional exercises may be confined to

those belonging to one watch. It is directed that, unless bad weather

prevent, Monday of each week be set apart for general quarters.

3. He will, at least once in two months for the first year of the

cruise, and once in three months for the remainder thereof, assemble

the crew at quarters in the night, without any previous intimation of

his intention to do so, and have a general exercise. He will inspect

the ship throughout, and cause an entry to be made in the log-book of

the length of time required between [4]the beginning of the call to

quarters and the complete preparation for commencing action; also,

when every gun is ready for a second fire.

4. In order to ascertain whether the equipments are complete and their

uses understood, as soon after the ship has been commissioned as

circumstances will permit, he will cause at least one round to be

fired, with shot or shell, according to the nature of the gun; and,

when practicable, at targets at known distances and with the

appropriate service charges. (See Tables of Ranges, Appendix.)

5. He will immediately endeavor to discover whether defects or

deficiencies in the armament or equipment exist, and, if any be found,

will remedy them as far as in his power consistently with

instructions, representing them to the Commandant of the yard of

outfit, if near it; and, if important, to the Chief of the Bureau of

Ordnance.

6. On the representation of the Gunner that the Ordnance Stores are

injured or liable to injury, he will order the survey called for by

Article 49.

7. He will, in each quarter of the first year of the cruise, expend in

target-practice six rounds, and in each succeeding quarter-year six

broadsides, making the report required by Art. 14.

He will not, however, either for this purpose or for saluting, reduce

his supply of ammunition below 100 broadsides.

8. In order to accustom the men to the use of loaded shells, they are

frequently to be used in preference to shot. For this purpose,

however, empty shells, or those that are “bouched” only, will be

carefully fitted, filled, and fused on board, in season, according to

the directions (Chap. I. Part III.), and first expended.

They should be fitted only as required to replace those expended; a

principal object in supplying a certain number of shells to be fitted

on board ships, is to disseminate information on this subject.

9. The relative proportions of “distant,” “ordinary,” and

“near-firing” charges are to be preserved (See Table of Charges,

Part III.) as nearly as practicable, and after action or exercise,

deficiencies caused by the expenditure of any particular kind of

charge will be made up, without unnecessary delay, from the others on

hand.

10. The allowances for target-practice are not to be expended in one

or two exercises, but are to be divided in such proportions as to

allow target-practice once a fortnight, or at least once a month, when

practicable; and at least three-fourths of the charges allowed shall

be expended in practice at sea, when it can be conveniently done,

opportunities being chosen for that purpose under all the

circumstances of wind and weather in which vessels of war are liable

to engage in battle.

[5]11. When in port, and circumstances will admit, such places are to be

selected for practice as are favorable for the recovery of the

projectiles; when the effect of the bursting charge is not important,

a blowing charge may be used in shells, to test the efficiency of the

fuze without destroying the shell.

In practice the service charges for which the sights are marked are

alone to be employed.

Distances within half a mile are preferable for solid shot, as best

showing the result. Targets of ten feet high by twenty long will

afford the means of general comparison, especially with the practice

at the experimental battery at Washington. For shells, the distances

should suit the ranges of their fuzes, or time of burning, that the

degree of certainty of explosion in direct or ricochet fire may be

seen and noted.

12. The whole crew is to be exercised in the use of the musket,

carbine, pistol, and sword, and in firing at a target with small arms,

by suitable persons, each division under the superintendence of its

respective commanding officer. The company and the battalion drill is

recommended as often as convenient opportunities of exercise present

themselves.

13. He will cause the boats’ crews to be exercised in all the

preparations for attacking an enemy, either by land or water, and in

the use of “boat and field howitzers,” and small arms, under all the

various circumstances likely to arise in such service, and

particularly in embarking and disembarking the “boat and field” guns

and ammunition. (See Part II.)

14. At the expiration of each quarter he will cause to be prepared,

and forward, by the earliest favorable opportunity, to the Bureau of

Ordnance, a report of all firing, with or without projectiles,

according to the detail given in form C. Appendix; also the Quarterly

return of receipts and expenditures in the Ordnance Department.

15. He will, once in every quarter, cause a thorough examination to be

made into the condition of the armament, shot and shells; and will see

that care is taken to keep the shot and shell lockers dry; that the

shot and shells stowed therein are clean and free from rust, and,

also, that the diameter of shot kept on deck is not increased above

the high gauge by injudicious lacquering or painting, and report to

the Bureau of Ordnance that this has been done.

16. He is to take care that especial attention is paid to the fuzes,

whether spare or in the shells; and if there be reason to suspect

injury from dampness or any other cause, he will have one or more

fuzes burned for trial.

17. He will not permit shells to be filled, or their fuzes to be

shifted or shortened, without his order; and whenever these operations

are to be [6]performed, he will see that a suitable and properly secured

place, not in the shell-room, and as far from the magazine as

convenient, is selected for the purpose. On such occasions the fires

and lights are to be extinguished, and also the further precautions

are to be observed, as to the manner of performing the work, contained

in the directions for filling and emptying shells. (See Chap. I.,

Part III.)

18. He is not to dismount, strike below, or otherwise render unfit for

immediate use, any of the guns on board the ship he commands, except

imperative necessity should require it for the safety of the vessel.

The particular circumstances of such necessity are to be immediately

entered at large in the log, and information is to be given to the

Commander of the squadron, and to the Secretary of the Navy.

When guns are to be struck below, or when shipped for transportation,

he shall cause all the precautions to be taken to guard them from

injury, prescribed in Article 46 of these instructions, and such

others as circumstances require.

19. He is prohibited from giving away the arms of any description

belonging to the vessel under his command.

20. He will keep the keys of the magazines and shell-rooms, and of the

receptacles for percussion caps and primers, and of the cocks for

flooding magazines and shell-rooms, in the cabin, where they may be

obtained by the Executive Officer in case they should be wanted when

the Captain is absent from the vessel; and they are only to be

delivered to the Executive Officer, or the Officer of the Powder

Division.

21. Before entering any friendly port, he will cause every gun to be

drawn and reloaded with cartridge, if necessary to salute.

22. He will not permit friction-matches to be on board under any

circumstances, and before sailing will notify all persons of this

regulation, and institute a search to see that it has been complied

with.

EXECUTIVE OFFICER.

23. The Executive Officer will, under the orders and direction of the

Captain, ascertain that all the ordnance stores and equipments ordered

or allowed for the vessel are received on board in good order; that

they are properly distributed and stowed; that they are only used or

expended according to directions from proper authority, and that they

are duly accounted for, according to the directions and forms which

are or may be prescribed by the Bureau of Ordnance. In small vessels

which have no Gunner, he shall receipt for and be accountable for all

ordnance stores, making all the returns which the Gunner is herein

directed to prepare.

[7]24. He will be particularly attentive to the state of the batteries,

small arms, magazines, shell-rooms, and shot-lockers; to the passages

leading to and scuttles connected with them; and take care that they

are kept clear and ready for action.

25. He will cause convenient places to be assigned for the stowage of

spare articles which may be required in action, and see that shot for

at least twenty broadsides for shot-guns, and one shell for each

shell-gun, are always in readiness upon the respective decks.

26. When salutes are to be fired he is personally to examine, or to

direct one of the Officers Commanding a Division to examine, ascertain

and report that the necessary preparations are made and precautions

taken to avoid accidents. The guns, if loaded, are to be drawn,

wormed, sponged and reloaded. They are, nevertheless, to be so laid as

to prevent the possibility of mischief, even in the contingency of a

shot or wad being left in any of them. Hard wads are not to be used in

firing salutes, nor are port-fires. The guns are to be fired either

with percussion or friction primers, as the Captain may prefer. These,

when in good order, are not apt to fail if the lock-string be properly

pulled; as, however, a slight deterioration may interfere with the

regularity of salutes, the precaution of dropping a few grains of

gunpowder into the vent will be found effectual.

Guns of the lowest calibre and class, when sufficient in number, are

to be used for saluting; and no heavier than their “near-firing”

charge is to be used. (See Table of Charges, Part III.) Two boats’

howitzers will be found sufficient for saluting. “Saluting powder” to

be used in all guns for this purpose, in preference to “Service

powder.”

27. In large vessels he will cause a cot with a spare sacking-bottom,

or such other apparatus as may be approved by the Surgeon, to be

prepared and kept for the purpose of lowering the wounded to the orlop

or berth deck.

28. Before the powder is received on board, he, with the Gunner, will

carefully inspect the magazines and shell-rooms, their passages and

light-rooms, and have them thoroughly cleaned, dried and aired, and

will see that the pipes and stop-cocks, and every thing connected with

flooding the magazines, are in order, and acquaint himself with their

position and mode of operation; the lighting apparatus cleaned and

dried; and particularly that the glasses for transmitting light into

the magazines and shell-rooms are clear and without fracture; that the

light burns clearly, and the box is well ventilated; and shall report

to the Ordnance Officer when the magazines are ready to receive the

ammunition. (See Chap. II., Part III.)

OFFICERS IN CHARGE OF DIVISIONS.

29. Officers in charge of divisions of guns are required to make

themselves thoroughly conversant with every particular relating to the

equipment, exercise, and management of the guns, as set forth in these

instructions, and especially to familiarize themselves with the

charges prescribed and the ranges given in the Tables; the principles

and practice of pointing guns under all circumstances, and also with

every precaution connected with the use of shells, and of percussion

and time fuzes.

30. They are carefully to inspect their divisions when called to

quarters for inspection or exercise, and see that every thing is, at

all times, in place and in order for service; and in case of

discovering any defect or deficiency, will report it to the Executive

Officer.

31. They will be careful, when instructing the men at quarters, to

require a strict adherence to the prescribed mode of performing their

duties, and to all the details of execution, in order that general

uniformity and the efficiency dependent on it may be secured. When the

individuals of the guns’ crews have become expert in the performance

of their particular duties, then each man shall be instructed by the

officer of his division, until he shall have become acquainted with

the special duties of every station at the gun.

32. They are at least once a week to examine the guns and all the iron

work of the carriages, and see that they are kept free from rust, and

especially the eccentric axles, elevating screws, and pivot-bolts,

which must be protected by a mixture of tallow and white-lead, or

other similar coating. The cap-squares must be frequently removed, the

guns lifted and the trunnions cleaned; the elevating screws oiled, but

never cleaned with brick or emery paper.

Once a quarter at least, all the connecting bolts, such as cap-square,

bracket, breast, and transom bolts, are to be examined and tightened

if they require it. To do this it is necessary, after lifting the gun,

to turn the carriage bottom up. The threads of the screws of the bolts

above named must be coated with the lacquer for small arms.

33. The Officer of the Powder Division will, in like manner, carefully

instruct and drill his men, and test the efficiency of the

arrangements for passing powder, shot, and shell, in order to insure a

sufficient supply of each to all parts of the batteries, without the

danger of misdirection or of accumulations in any part thereof. To

this end blocks of proper shapes and colors may be provided in the

appropriate tanks of the magazines, and passed up instead of powder,

when that is not used. These are to be counted and reported by the

Officers of the Gun Divisions, and will enable the [9]Executive Officer,

and the Officer of the Powder Division, to detect and remedy defects

or deficiencies in the system or its details, and to be sure that the

men are properly stationed and instructed.

MASTER.

34. The Master will see that the number of fighting-stoppers, whips

for preventer-stays, preventer-braces, slings for yards and gaffs,

relieving-tackles, and other articles in his division which are

directed, are all fitted and ready for use in action. At general

quarters his division must be regularly drilled in fishing masts and

spars, stoppering and knotting rigging, and trimming sails.

CHIEF ENGINEER.

35. The Chief Engineer will ascertain that all the tools and

implements necessary for the prompt and effectual repair of injuries

which the engine and its dependencies may receive in action, are

received on board and placed at hand.

GUNNER.

36. He shall attend personally at the ordnance store where his stores

shall be delivered to him, the Ordnance Officer furnishing him with

means of transportation and men for stowing them in their appointed

places on board ship, when the crew is not available for this purpose.

He is to be especially careful that the equipments and stores

belonging to the magazine are arranged therein in conformity to

Ordnance Instructions. (See Chap. I., Part III. for further

directions relative to his duties and responsibilities.)

37. The powder-tanks containing charges for each class of guns are to

be stowed on their sides, with the lids next the alleys and hinges

down, near the magazine scuttles through which these charges are to be

delivered; the charges for “ordinary firing” nearest the scuttle. When

tanks are emptied they are to be stowed on the upper shelves in order

that the powder may be kept, as much as possible, below the water

line.

38. In time of war, passing-boxes are to have charges for “ordinary

firing” kept in them ready for passing up at once.

39. In future white will be used for all cylinders, the calibre and

weight distinctly stencilled on each bag. In case of a deficiency of

white cartridge cloth, the different charges for all classes of guns

may be distinguished by the color of the cartridge-bags; white being

used for distant firing, blue for “ordinary” firing, and red for

“near” firing.

The lid ends of the powder-tanks for service charges are to be painted

of [10]the same colors as the cartridge-bags which they contain, and must

be distinctly marked with the calibre and weight of the gun for which

the cartridges are intended. Tanks for musket-powder must be marked

MUSKET-POWDER; and this powder may be put up in either of the kind of

charges allowed which will make the best stowage, the bags properly

stencilled.

Tanks containing saluting powder are to be marked “SALUTING.” It is to

be kept in bags, stencilled “saluting.”

40. No loose powder is ever to be taken or carried on board ship, and

all, whether public or private belonging to officers, must be safely

stowed in the magazines.

41. All metallic cartridges for small arms, percussion caps, and

percussion or friction primers, or other articles containing

fulminating matter, must be kept in boxes prepared for the purpose,

and the boxes must be stowed separately from other articles, in a dry,

secure, and safe place, under lock and key, and are on no account to

be put in the magazine. It is recommended that they be distributed in

two or three places, a portion conveniently at hand.

42. The fireworks, after carefully removing all fulminating matter,

such as caps or primers, if any such be used to ignite them, are to be

stowed in their proper packing-boxes in other light boxes of suitable

length, made water-tight, with lock and key, and to fit between the

beams and carlines of the gun decks of frigates and berth decks of

single-decked vessels. Those for instant use must be placed near the

after hatch, and the remainder abaft that position, if possible, so as

to be constantly under the care of the sentinel at the cabin doors. In

no case, however, are they to be placed over any standing light or

lantern on any deck.

43. All ammunition packing-boxes, shell-bags, and metal cases are to

be preserved, and returned into store at the end of the cruise.

44. No coopering is ever to be done in the magazines of ships. Should

powder be received on board in barrels, the hoops and heads must be

started on the orlop or berth deck before entering the magazine.

45. In stowing shell-rooms, filled shells are to be stowed together in

boxes or bags; those having fuzes of different times of burning, and

each kind of fuze, will be placed in tiers or ranges distinctly

separate. (See Article ON FUZES, C. IV.) Empty shells are to be

stowed by themselves, unsabotted, in bulk, in a dry place.

46. Whenever guns are to be struck below, or prepared for

transportation, the gunner will see that the bores are washed with

fresh water, carefully sponged, thoroughly dried, and coated with

melted tallow, and a wad dipped in the same material inserted, and

connected with a tompion by a lanyard. He is to see that the tompion

is put in securely, and the vent and all screw-holes stopped by a plug

of soft wood, and puttied over.

47. He is to examine and report daily, before 10 A.M. and 8 P.M.,

whether the guns and all their equipments; the whips for supplying

shot and shells; [11]the arm-chests, armory, and small arms; the supply

and reserve division boxes, and other articles furnished as ordnance

and ordnance stores, are in good order and in place, and make

immediate report to the Commanding or Executive Officer of any defects

or deficiencies which he may discover at any other time.

48. The guns and their equipments are to be kept as dry as possible,

and no salt water used in cleaning them.

49. If he shall discover any articles to be injured, or liable to

injury from any cause, he will ask, in writing, for a survey to be

held, to determine the amount, cause, or liability of any of the

stores or equipments to damage or deterioration; a copy of this

request and report of survey to be furnished to him as a voucher, by

the officer ordering the survey.

50. Whenever the magazines or shell-rooms are opened, he is to take

every precaution to guard against accident by fire; to examine

particularly that all the men stationed in any way in or about the

magazine, embracing all stationed within the magazine screen, put on

the magazine dress and shoes, and on no account have any thing

metallic about them, and that no improper articles are introduced. He

will also see that all the articles required for sweeping and removing

loose powder are at hand, and that those operations are performed

before the magazine is closed.

51. The tanks are never to be opened unless by special order, or when

powder is actually required for service; and then no more of the lids

are to be unscrewed than is necessary for immediate supply. The

strictest attention to this regulation is required of the Gunner, as

experience has proved that the preservation of the powder in good

condition depends upon the entire exclusion of damp air.

52. When the guns are ordered to be drawn before entering a friendly

port, the Gunner is to be particularly attentive to assure himself

that no shot or wad is left in any gun.

53. In saluting, he is to guard against accident in loading, pointing,

and firing, and to be particularly careful in reloading, where that

operation is unavoidable.

54. In the absence or illness of the Gunner, his general duties will

devolve on a Gunner’s Mate, under the supervision of the Executive

Officer.

55. The Gunner shall keep a minute-book of all expenditures in the

Ordnance Department, and on Monday of each week shall submit it to the

Executive Officer for examination and approval. Within ten days after

the expiration of the quarter, he shall make out his quarterly return

in the required form, which shall be signed by him, certified correct

by the Executive Officer, approved by the Commander, and forwarded to

the Bureau by the first opportunity. At the same time the ledger shall

be posted.

[12]56. When a vessel returns from a cruise to be refitted or repaired, or

placed in ordinary, the Gunner, or person performing the duty of

Gunner, is not to leave the ship, unless specially authorized by the

Secretary of the Navy, until all the guns, powder, small arms,

ammunition, and other articles under his charge, shall have been

examined and surveyed, and turned over to his successor, or other

person appointed to receive them, or to the Inspector of Ordnance, the

receipt for which he shall show to the officer to whom he applies for

leave.

CARPENTER.

57. The Carpenter shall ascertain and report to the Executive Officer

that there are a sufficient number of tarpaulins to cover all the

hatches leading to the fore and after orlops; that the pump-gear of

every description is ready and in order for rigging the pumps, and

that every preparation can be promptly made before going into action

to free the ship, in case of receiving injuries below the water-line.

58. He is also to examine and keep in order the force and channel

pumps, the fire-engine, the division-tubs, and, in short, all the

apparatus necessary to give a good and speedy supply of water in case

of fire in action.

59. He is specially charged with the care and distribution of articles

for stopping shot-holes or repairing other injuries to the hull, which

may be received in action, viz.: shot-plugs and mauls; pieces of pine

board from eighteen inches to three feet long, and from twelve to

fifteen inches wide, covered with felt or fearnaught, previously

coated with tar or white lead; patches of sheet-lead, all with

nail-holes punched; and trouser-slings for lowering men outside the

vessel, to be provided with a pouch or pocket, to contain a hammer and

nails. Tarred canvas or oakum should be prepared to shove into the

shot-holes before the patches of board or lead are nailed on. Although

shot-plugs are still to be allowed, the means just described are most

to be relied on.

60. In case it shall not have already been done, the Carpenter, under

the direction of the Commander or Executive Officer of the ship, will

draw a black line, two inches broad, on the ceiling of the ship, to

correspond with the ordinary height of the water-line. On this is to

be marked, by corresponding intervals and numbers, the position of the

ports on the lowest of the gun-decks. By this arrangement the position

of the shot-hole can be easily ascertained and communicated, through

the Officer Commanding the Powder Division, and a remedy promptly

applied. To this end he is to pay habitual attention to keeping the

wings clear to four feet below the water-line, and report any

obstructions to the Executive Officer.

YEOMAN.

61. The Yeoman is to charge himself with, and is to be accountable

for, all articles of ordnance stores which may be placed in the

storeroom under his charge, and is not to issue or expend any article,

except by order of, or authority from, the Captain or Executive

Officer.

62. On the return of a ship, to be laid up at a yard, or to be

refitted or repaired, the Yeoman will be retained to deliver the

ordnance stores in his charge into the hands of the Ordnance Officer.

If any deficiency in the stores under his charge be discovered, or

they are in bad order, the Ordnance Officer will report the same to

the Commandant of the yard, who will order a survey, to ascertain the

nature and extent of the deficiency, or injury, and whether either

were caused by the Yeoman’s negligence or fault. If the surveying

officers shall find just cause for suspecting fraud or negligence, the

Commandant shall suspend the payment and discharge of the Yeoman,

until he shall report the case to the Bureau and receive the orders of

the Department.

63. No person is to be knowingly appointed Yeoman who has already

served in that capacity in any vessel of war of the United States, who

cannot produce a satisfactory certificate of his former good conduct

as Yeoman.

CHAPTER II.

GENERAL DISTRIBUTION OF OFFICERS AND MEN AT QUARTERS.

64. The following directions for the general distribution of a ship’s

company at quarters, or for action, are intended to secure, upon the

most important points, a degree of uniformity which will promote

efficiency, and at the same time leave to the Captains the selection

and arrangement of many individuals under their command, according to

their own views of the particular qualifications of each.

65. The Captain’s station, in action, is upon the quarter-deck.

66. The Executive Officer, the Midshipmen acting as Aides to the

Captain, and the Signal Officer, are also to be stationed on the

quarter-deck.

67. The stations of the other Officers are to be regulated by

divisions, as follows:

The guns upon each deck are to be numbered from forward, beginning

with No. 1, and continuing aft, in succession, each gun and its

opposite being designated by the same number, excepting pivot and

shifting guns, each of which is to have a separate number. The guns on

each deck are then to be divided as equally as possible into three or

two divisions, according to the number of Lieutenants or other Watch

Officers on board, so that each division of guns, and the persons

belonging to it, may be commanded by a Lieutenant or other Watch

Officer. These divisions are to be numbered consecutively, designating

the forward division on the lowest gun-deck as the first division, and

passing from the after division of one deck to the forward division of

the next deck above it.

68. The command of these divisions of guns is to be assigned, in the

order of their numbers, to the Lieutenants or other Watch Officers,

according to their rank, assigning the first division to the officer

next in rank to the Executive Officer. In case of a deficiency of

Watch Officers, the quarter-deck division may be assigned to an Ensign

or Midshipman, who will act under the general supervision of the

Executive Officer. When the number of officers on board of vessels

having pivot-guns will permit, each pivot-gun will be placed under the

special charge of a suitable officer of the division of which it forms

a part.

MASTER’S DIVISION.

69. This division will comprise all those stationed in the tops, and

those appointed to attend to the rigging, sails, steerage, and

signals. The Master is to be stationed on the quarter-deck, and to be

assisted by the Boatswain, whose station will be on the forecastle.

The Boatswain will be charged with all his divisional duties in the

event of his death or absence. (For Arms, see Table in Article 101.)

POWDER DIVISION.

70. This division will be under the direction either of a Lieutenant,

Master, Ensign, or competent Midshipman. It will consist of all those

stationed below the gun-decks, except persons belonging to the

Surgeon’s Division and the Paymaster and his Clerk.

The Gunner is to be stationed in the main magazine, and a Gunner’s

Mate or Quarter Gunner in the other magazine when there are two; and

those persons of this division who may be stationed in the magazines

and passages are to be under the immediate direction of the Gunner and

his Mate, respectively. Those of the Carpenter’s crew stationed in the

hold or wings are to be under the immediate direction of the

Carpenter’s Mate, who will be stationed with them. All reports,

however, are to be made through the Commanding Officer of the

division.

DIVISION OF MARINES.

71. All the Marines who may not be distributed to other divisions for

action are to compose a Division of Marines, to be under the immediate

command of the Senior Officer of Marines on board. He will form his

division on such part or parts of the spar or upper deck as the

Captain may direct.

SURGEON’S DIVISION.

72. The SURGEON or senior Medical Officer will have the direction of

this division, which shall comprise all the Medical Officers and such

other persons as may be designated by the Captain to assist in the

care of the wounded in action. This division will occupy the cockpit,

or such other convenient place as the Captain of the vessel may

direct.

THE CHAPLAIN.

73. The CHAPLAIN will be in attendance to perform the duties of his

sacred office, and to render such other service as may be in his

power.

PAYMASTER.

74. The PAYMASTER’S station will be in the ward-room and on the

berth-deck, in charge of the money, books and stores belonging to his

Department.

ENGINEER DIVISION.

75. The Engineer Division shall be under the direction of the Chief

Engineer, and shall comprise the Assistant Engineers and such of the

Firemen and Coalheavers as may be detailed for the purpose. An

Assistant will be appointed to take charge of the fire party detailed

from this Division.

MISCELLANEOUS OFFICERS.

76. Ensigns, Midshipmen, Mates, Captain’s and other Clerks, the

Sailmaker, and other officers not enumerated, are to be assigned to

the different divisions at the discretion of the Captain.

77. In distributing the Petty Officers, Seamen, and others to the guns

and other stations in the several divisions, it is desirable, as a

general rule, that those stationed at the same gun or near each other

at quarters, should be drawn from different stations for working ship;

so that a great loss at any one gun may not fall too heavily on any

watch station.

Exceptions to this general rule may be advantageously made where the

duties of men require their habitual attendance on particular decks.

In such cases it will generally be advisable to station them at

quarters near to the places of their ordinary duties.

DISTRIBUTION OF THE CREW.

78. Table showing the number of men for the service of each kind and

class of gun in use in the Navy, assuming the vessel to have the

established complement.

| Pivot Guns: | Broadside Guns: | ||

| XI-inch of 16,000 lbs., X-inch of 10,000 lbs. |

24 | IX-inch of 9,000 lbs., 100-pdr. rifle. |

16 |

| X-inch of 12,000 lbs., 64-pdr. of 106 cwt. |

20 | 8-inch of 68 cwt. | 14 |

| IX-inch of 9,000 lbs., 100-pdr. rifle. |

16 | 8-inch of 6,500 lbs., 8-inch of 56 cwt. |

12 |

| 60-pdr. rifle. | 10 | 32-pdr. of 57 cwt. | 12 |

| 30-pdr. rifle. | 8 | 32-pdr. of 4,500 lbs., 32-pdr. of 42 cwt., 60-pdr. rifle. |

10 |

| 20-pdr. rifle. | 6 | 32-pdr. of 33 cwt., 30-pdr. rifle. | 8 |

| 32-pdr. of 27 cwt., 20-pdr. rifle. | 6 | ||

[17]To the XI, X, and IX-inch 100-pounder rifle, and 64-pounder pivot

guns, a Powderman, and to all other guns a Powder-boy is to be added.

The number of men to form crews of guns mounted on carriages of

special character, is to be regulated as may be found most

advantageous by the Commanding Officer.

79. In designating the Petty Officers and others for particular

stations, it is assumed that the intelligence, skill, and force of the

men have been equally divided between the two watches, and that the

men in the starboard watch have all odd numbers, as 1, 3, 5, and those

of the port watch even numbers, as 2, 4, 6.

To preserve this equality, and to secure the ability of those who may

be upon deck to prepare the ship for action at night, whilst the watch

below are bringing up and stowing the hammocks, all the odd-numbered

guns will be entirely manned by men belonging to the starboard watch,

and all the even-numbered guns by those belonging to the port watch,

as far as practicable. The crews of pivot-guns to be taken half from

each watch.

80. Where ports on opposite sides of the same deck are numbered the

same, and are both provided with a gun, guns’ crews are only to be

furnished for the guns on one side. Pivot and shifting guns are each

to have full guns’ crews.

81. When the complements allowed to vessels of the Navy will permit,

it is recommended as a general arrangement that the guns’ crews be

formed of about one-third Petty Officers and Seamen, one-third

Ordinary Seamen, and one-third Landsmen and Boys, and that this system

be observed as nearly as practicable.

82. At least one Quarter Gunner should be stationed at each division

of guns; and a Gunner’s Mate or Quarter Gunner in the smaller

magazine, and in each shell-room.

If there be more shell-rooms than there are disposable Quarter Gunners

to attend them, other careful and suitable persons are to be selected

to supply the deficiency.

83. Before permanently assigning the individuals which form a gun’s

crew, to the performance of particular duties connected with its

service in [18]action, it is important to ascertain their respective

qualifications, as far as may be practicable, by questioning them or

by exercising them at the guns.

84. The Captains, especially, should be selected from those in whose

skill, coolness, and judgment the greatest reliance can be placed,

without regard to their ratings, though at the same time care should

be taken to avoid stationing men of a higher rating than the Captains

of the guns, to perform subordinate duties at the same guns. They

should be examined by the Surgeon with reference to eyesight.

Spongers and Loaders rank next in importance, and, with activity and

coolness, should possess the necessary physical strength and stature.

For Handspikemen, weight is important, in addition to strength and

coolness.

85. Very careful men should be selected for attending the

Powder-scuttles on the different decks, as well to prevent noise and

contention among the Powder-boys as to guard against accidents, and

speedily to repair such as may occur. The boys should be trained to

fall into line, to insure an equal distribution of powder.

86. Unless some special reason should require a different arrangement

with regard to Boarders, Pikemen, Firemen, Sail-trimmers, and Pumpmen,

the following will be observed:

BOARDERS.

87. Half the men composing a gun’s crew, excluding the Powderman or

Boy, are to be Boarders. When this rule gives an odd number of men,

the odd one is to be a Second Boarder.

88. The Boarders are to constitute two divisions, called First and

Second Boarders.

89. First Boarders are, generally, to be taken from the second part of

a gun’s crew; and Second Boarders from the first part.

90. All Petty Officers on the spar-deck, except the Quartermaster at

the conn and the Quartermaster at the wheel, are to be First

Boarders.—(For Arms of Boarders, see Table, Article 101.)

The Executive Officer leads the Boarders. All the Division Officers on

the spar-deck shall be First Boarders, except the officer commanding

the quarter-deck division, who shall lead the Pikemen. On gun-decks

the officer commanding the second division shall be a First Boarder;

the commanding officers of the other divisions shall be Second

Boarders. If there are two officers in any division, the second shall

lead those Boarders who do not go with his principal. A Lieutenant or

other responsible officer should be detailed to command the gun-deck

in the absence of the boarders and pikemen.

PIKEMEN.

91. One-fourth of the number of men composing a gun’s crew, rejecting

fractions, and excepting the Powderman or Boy, and all the men of the

Master’s division on the spar-deck, except those designated as

Boarders and those at the wheel and conn, are to be Pikemen, and

compose but one division.

92. For each Pikeman at a gun there is to be a musket or carbine

provided, which in action, when not in use, is to be kept with the

bayonet unfixed, hooked securely against a carline or beam near the

gun; or on a spar-deck placed conveniently at hand. When they are

called away they will repair on deck with these arms, when, if

ordered, they will place them in a secure place, to be designated by

the Executive Officer, and arm themselves with pikes. Pikemen will

wear a cartridge-box whenever at general quarters or in action.

Pikemen of the spar-deck divisions will, on being called away, arm

themselves as directed.

Should it become necessary, in an emergency, to call “all hands” from

below to repel an enemy, the Pikemen will, if not already so armed,

arm themselves with muskets or carbines, leaving their pikes to be

used by those whose arms are not designated—that is, by the remainder

of the gun’s crew and Powder Division.

93. One boarding-pike for each gun on covered decks is always to be

kept triced up conveniently near it, and this is to be used by the

Powderman, or any other person left at the gun to guard the port.

94. Pikemen are to be covered by the Marines with their bayonets

fixed.

FIREMEN.

95. With broadside guns, one Fireman is to be taken from each gun’s

crew, and from pivot-guns two. Each Fireman is to have a fire-bucket

at hand near his gun, and to wear his battle-axe in a belt around his

waist.

SAIL-TRIMMERS.

96. In all vessels there shall be two divisions of Sail-trimmers,

composed of all the men at the spar-deck guns, except 1st Captains,

1st Spongers, 1st Loaders, and Powder-boys. The 1st Sail-trimmers are

to be taken from the guns on the forward half, and the 2d

Sail-trimmers from those on the after half of the spar-deck.

97. In vessels carrying guns on more than one deck there are to be

three divisions of Sail-trimmers, called 1st, 2d, and 3d

Sail-trimmers, and the third division is to be made up of one man from

each gun’s crew on the other deck or decks, as designated in the

tables.—(Article 101.)

[20]This third division of Sail-trimmers is to be regarded as a reserved

force, and is not to repair on deck at the general call for

Sail-trimmers, nor except when specially ordered. Besides serving to

re-enforce the other two divisions when absolutely necessary, it is

also to re-enforce either the Firemen or the Pumpmen in cases of need.

98. The third division of Sail-trimmers, and all the Pikemen of the

guns’ crews, and others armed with muskets (See Tables, Article

101), may be made to assemble together as a body of Musketeers, either

for landing or otherwise. No one gun more than another will be

weakened by so doing; and this suggests the propriety of preferring

these men ordinarily for the crews of boats.

PUMPMEN.

99. Each gun’s crew composed of as many as 14 men is to furnish two,

but, when of less than 14 men, one Pumpman only.

100. When Pumpmen are sufficiently numerous to admit of working the

pumps with one-half their force, they should compose two divisions, to

be called 1st and 2d Pumpmen.

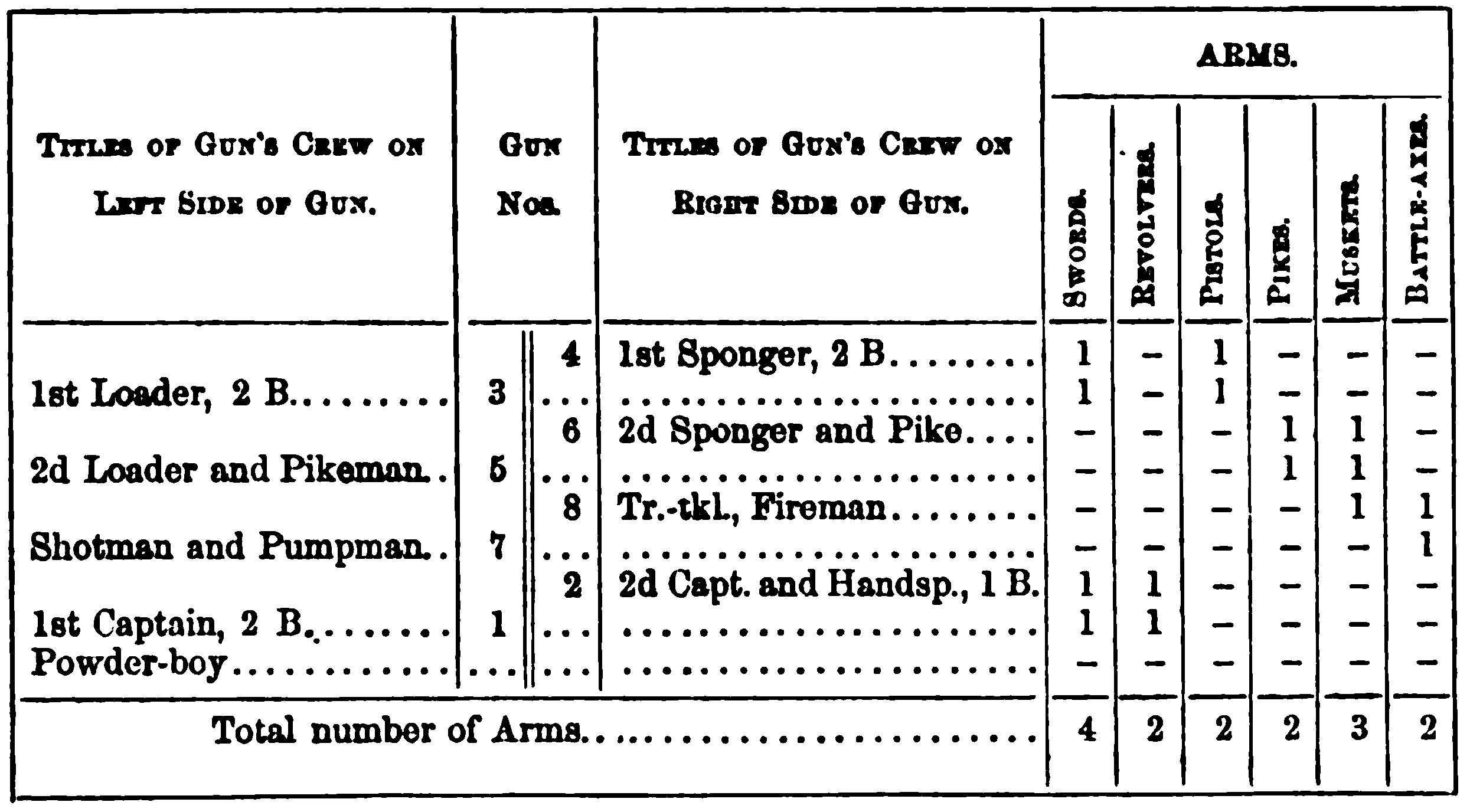

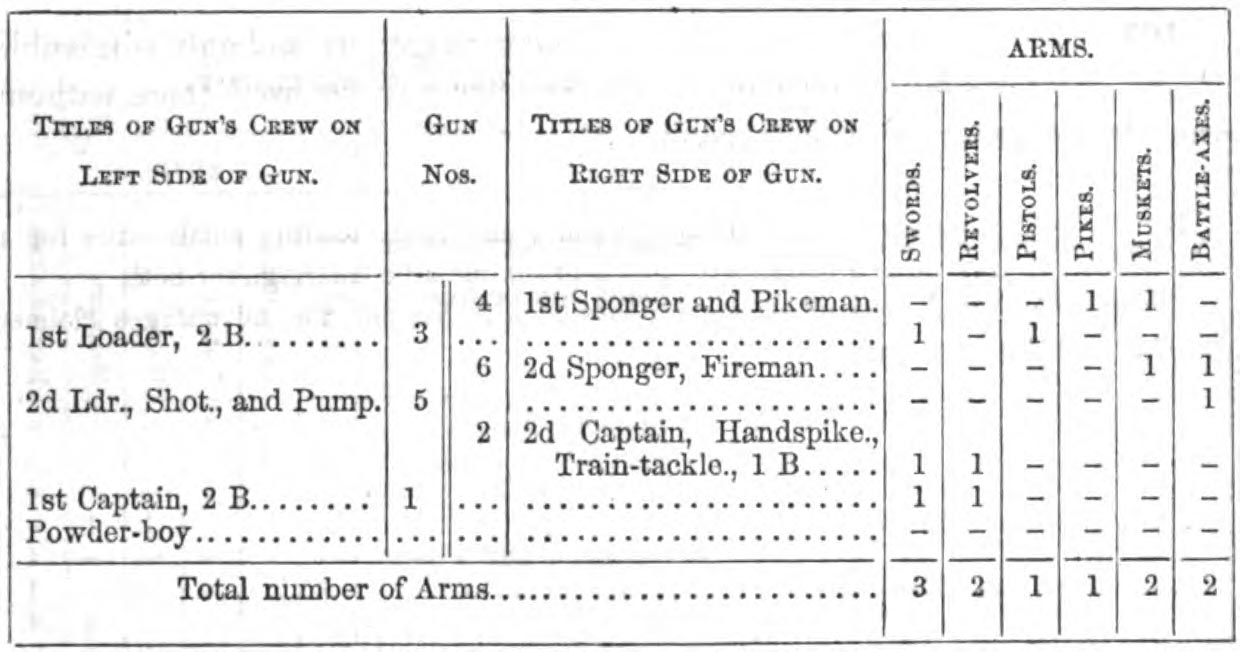

DISTRIBUTION AND ARMS OF MEN AT THE GUNS.

101. The annexed Tables show the stations of guns’ crews at

pivot-guns, and at broadside-guns, when composed, respectively, of the

following numbers of men: 24, 16, 14, 12, 10, 8, or 6; how each man of

a gun’s crew is to be armed, and the number of small arms of all kinds

required for each gun’s crew.

N.B.—To these Tables is annexed another, showing the small arms of

the Master’s Division.

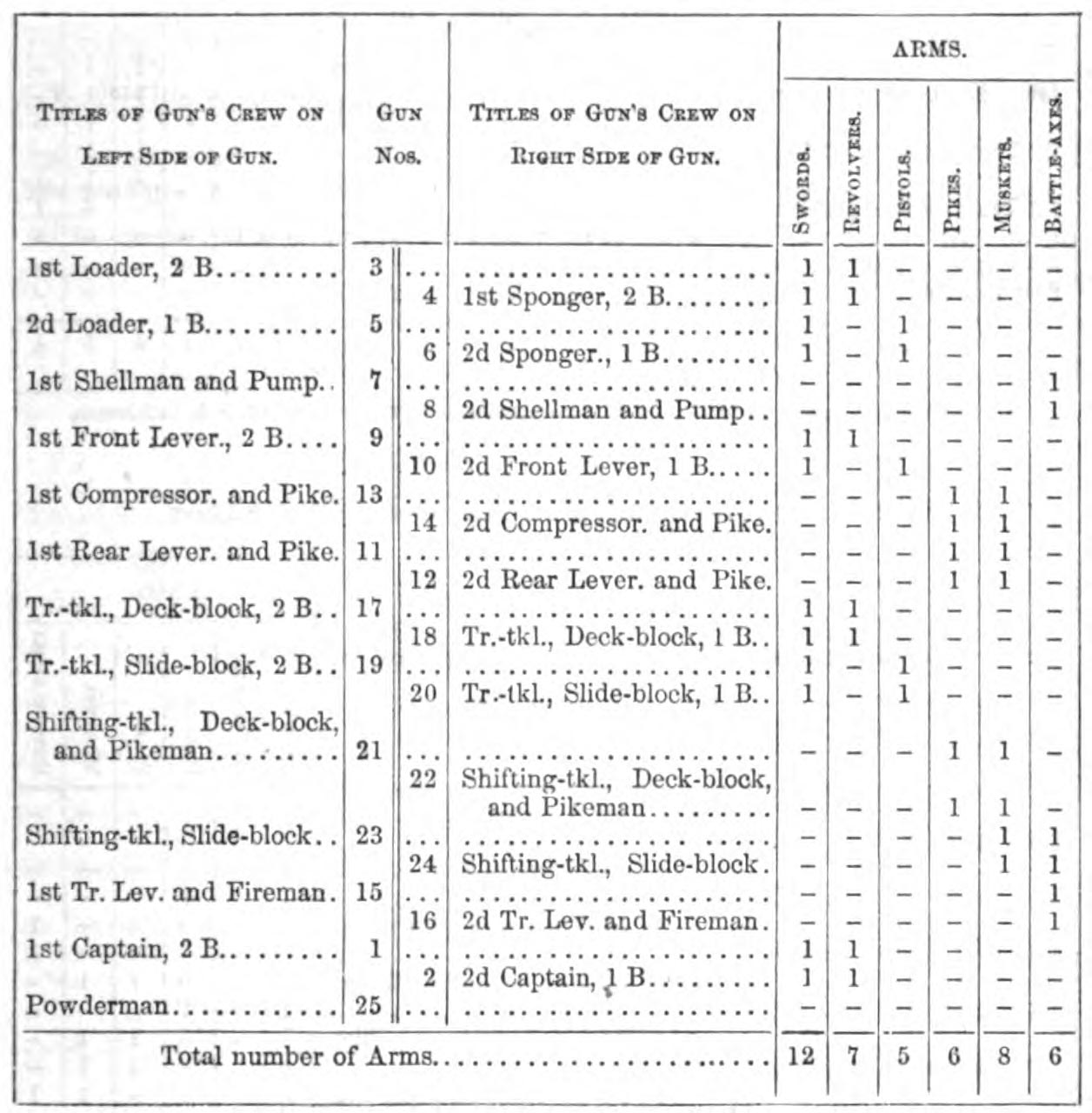

Pivot-Gun’s Crew, composed of 24 Men and a Powderman.

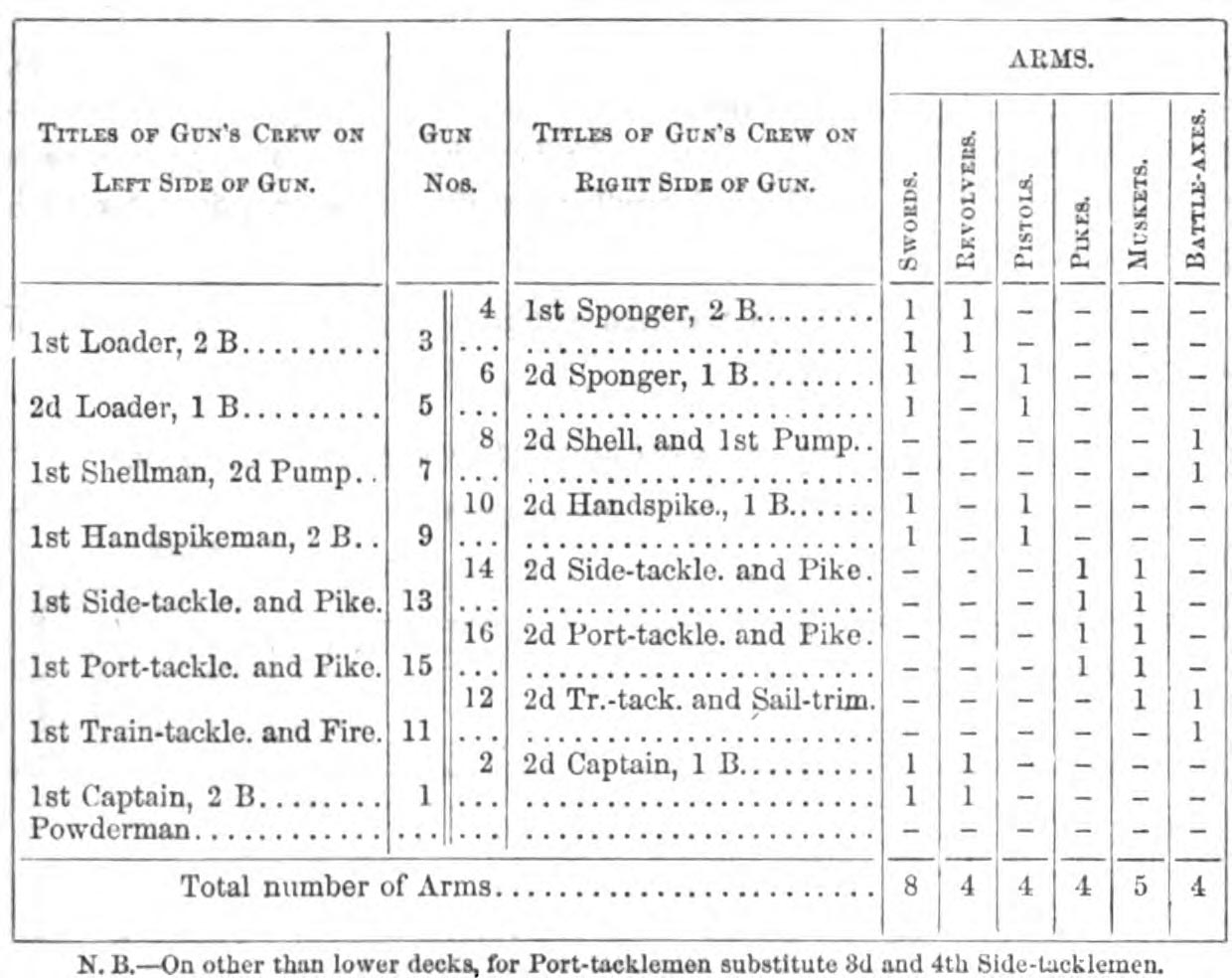

Gun’s Crew composed of 16 Men and a Powderman.

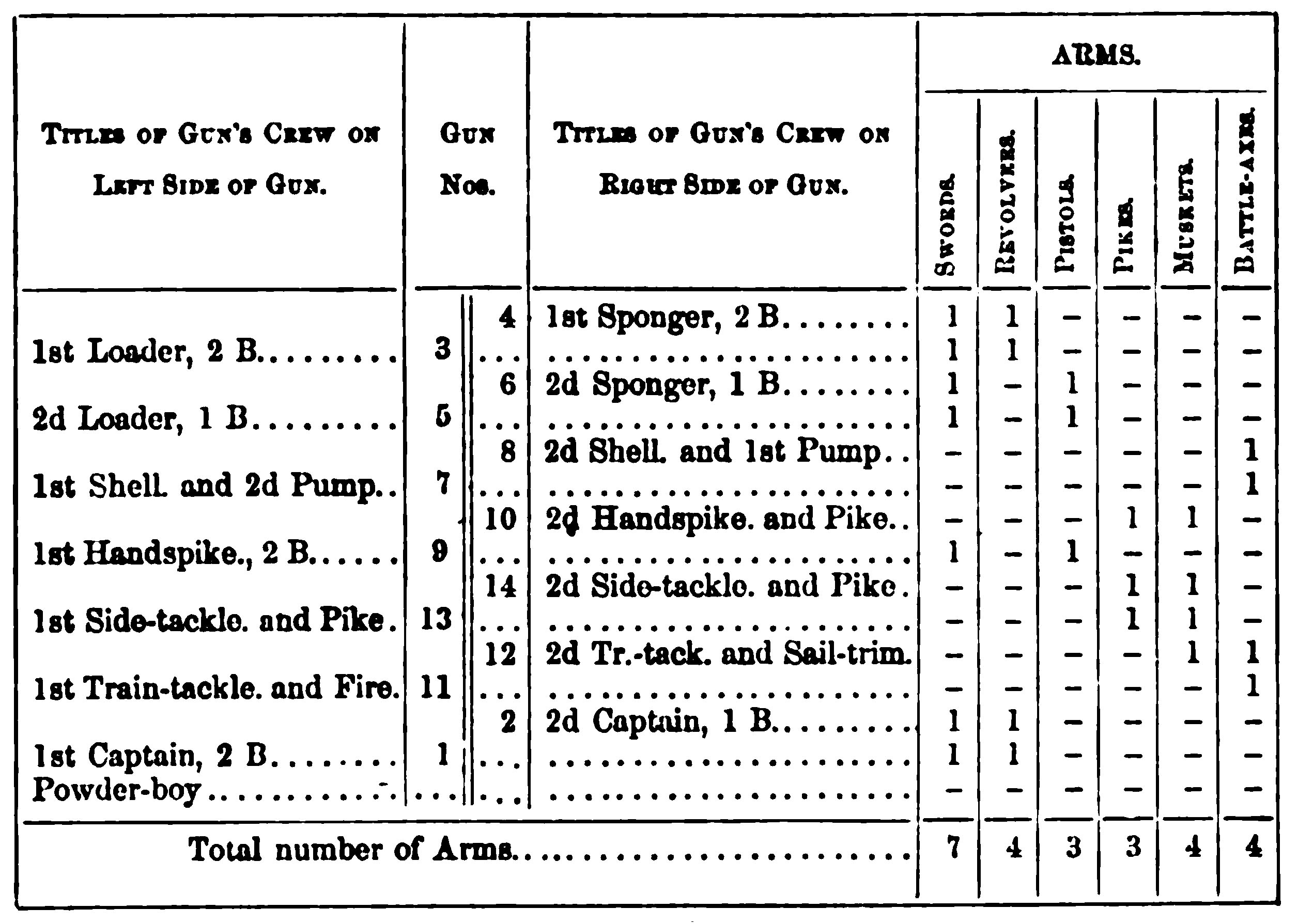

Gun’s Crew composed of 14 Men and a Powder-boy.

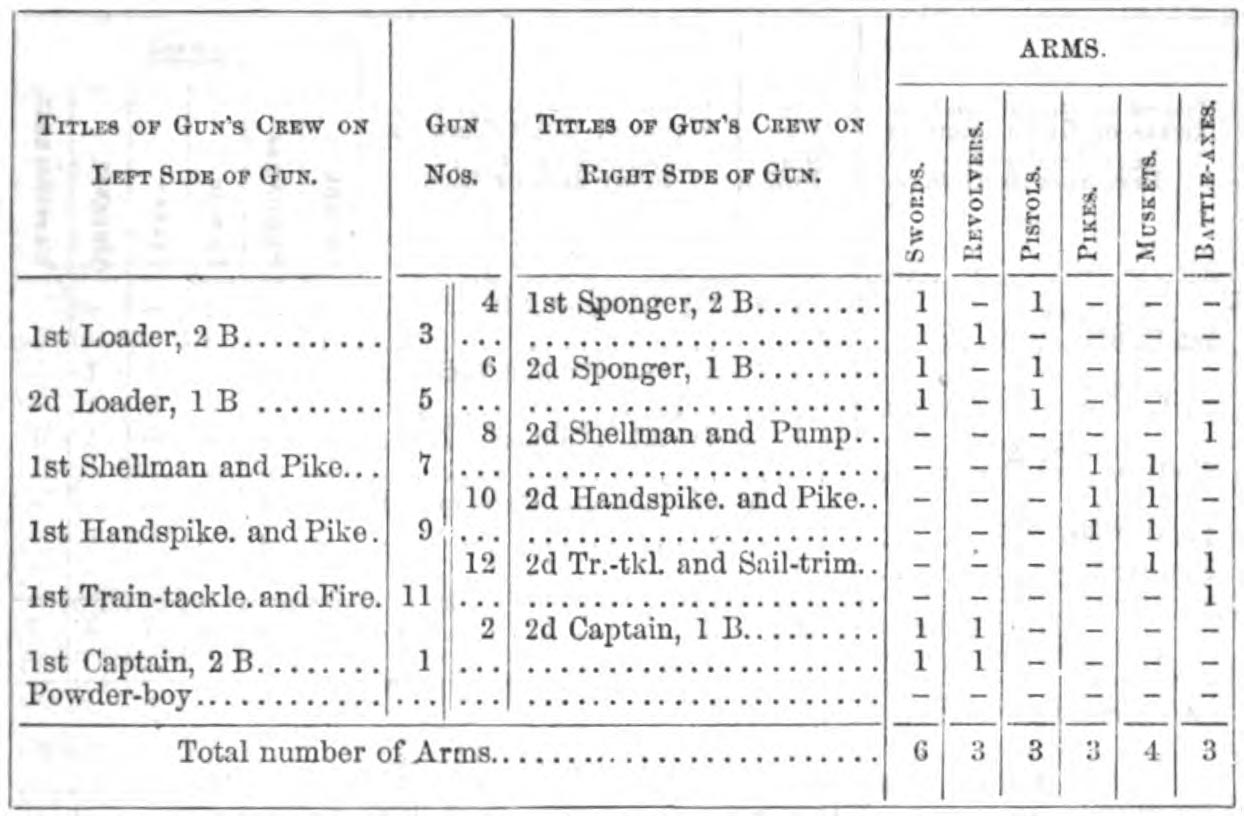

Gun’s Crew composed of 12 Men and a Powder-boy.

Gun’s Crew composed of 10 Men and a Powder-boy.

Gun’s Crew composed of 8 Men and a Powder-boy.

Gun’s Crew composed of 6 Men and a Powder-boy.

Small Arms of Master’s Division.

| Stations. | Ratings. | Arms. |

| Conn | Quartermaster | Pistol and Sword. |

| Wheel | Quartermaster and Seamen | Pistol and Sword. |

| Signals | Quartermaster | Pistol and Sword. |

| Signals | Boys | Pikes. |

| Relieving Tackles | Quartermaster and O.S. | Swords. |

| Main Braces | C.A.C. | Pistol and Sword. |

| Mastmen | B.M. | Pistol, sword, and Battle-axe. |

| Mastmen | Seamen and O.S. | Pikes and Battle-axes. |

| Topmen | Seamen and O.S. | Muskets |

| Forecastle | C.F. | Pistol and Sword. |

| Bell | S.C. | Pistol and Sword. |

[Note.—It is proposed to abandon the pike and all

muzzle-loading small arms for a breech-loading carbine and

pistol, with one uniform metallic cartridge for both.

The revolver pistol does not realize in service with seamen

the advantages claimed for that description of arm.]

102. The Captain will designate the different hatchways which shall be

used by the Boarders and others from each gun when they are called

upon deck at quarters. Cutlasses should not be drawn nor bayonets

fixed until ordered, and, in moving from one part of the deck to

another, should be sheathed, to avoid accidents.

103. The use of fire-arms in the tops being dangerous, and only

admissible under very peculiar circumstances, they are never to be

used there without the express direction of the Captain.

CHAPTER III.

DUTIES AT QUARTERS, IN BATTLE OR EXERCISE.

CAPTAIN.

104. The Captain, when at general quarters, either for exercise or in

action, is to superintend and take the general direction of every

thing connected with the management of the ship and the service of her

armament.

105. He will from time to time carefully inspect the ship, in order,

before commencing a general exercise, to ascertain that all the

required and proper preparations have been made for battle. When time

and other circumstances will permit, he will always make this

inspection before going into action, and when prevented from making it

personally, he will direct it to be made by the Executive Officer.

106. When engaged with an enemy at so great a distance as to require

the guns to be elevated, he will, if practicable, cause the distance

to be ascertained by observation, and, when that cannot be done, will

estimate the distance, and from time to time send directions to the

Officers of gun divisions for what distances the sights of their guns

should be set, and the nature of the projectile, and, if a shell be

used, the time of the fuze (See Article 326), and also the

cartridges to be used, whether for “distant,” “ordinary,” or “near”

firing.

107. He will determine and direct when two shot may be fired; when

“quick-firing” may be permitted; when small arms shall be distributed

and loaded; when Boarders shall be called up, and when they shall

assail an enemy. He will receive, through the Executive Officer, the

reports from all Officers commanding divisions.

EXECUTIVE OFFICER.

108. The Executive Officer, under the direction of the Captain, and

with the aid of the Master, will work the ship when in action or at

general quarters. He will receive the reports of the officers of the

different divisions and others, and communicate them to the Captain of

the ship.

SIGNAL OFFICER.

109. The Signal Officer is to see that every thing is prepared for

making and answering signals promptly, and will make all such as the

Captain may direct. He will provide himself with a watch, pencil, and

signal note-book properly ruled.

110. He will note and report to the Captain all signals that are made

to or by other vessels of the squadron, or other vessels in sight, and

also note the time at which each signal was made. He will observe and

report any material change which may take place in the positions of

the vessels of the squadron, or of other vessels, and every event of

moment that may occur.

MASTER’S DIVISION.

111. The Master will cause the persons in his division to sling the

yards and gaffs, to stopper the topsail sheets, to lead out the

preventer and other braces, and will see that they are clear, and

toggled, to prevent them from unreeving.

112. He will have the fighting stoppers at hand in the chains and tops

for stoppering the rigging; hatchets and axes ready for clearing away

any casual encumbrances from the guns; axes and hatchets for this

purpose must be sharpened, covered with painted canvas, and labelled

“not for general use;” and will cause proper arrangements to be made

for applying and securing grapnels, if they should be required.

113. He will see that the hammocks are compactly stowed, covered, and

stopped down, and will cause the boat and boom covers to be hauled

over and securely stopped down; the relieving tackles to be hooked and

ready for use; a compass to be placed to steer by; and see the spare

tiller at hand, the chronometer and other instruments put out of the

reach of shot, and relieved as much as possible from the jar of the

guns.

114. In case the Captain should give orders for sending small arms and

ammunition into the tops, he will attend to having them sent there,

and will be watchful that they are not so used as to expose the sails

and rigging to danger from taking fire; and in order to furnish a

sufficient supply of water, in case of accident, he will have four

fire-buckets fitted for each top, with [28]lanyards long enough to reach

the water from the yard-arms, and these should be filled with water in

preparing for action.

115. On the probability of an engagement, when the ship is on

soundings, the Master will have the ground-tackling ready and clear;

boats ready for getting out, and every preparation made for towing,

warping, anchoring, and getting springs upon the cables; and have

leads and lines in the chains. If at anchor, he will have the boats

dropped astern, the oars secured to the thwarts, and, if directed,

have the plugs ready to be taken out that the boats may fill, and also

cause the spare spars to be put overboard.

116. Whenever the cables are bent, they shall be kept stoppered until

wanted for use.

117. In action, besides aiding the Executive Officer in working ship,

the Master is to pay special attention to the steerage of the vessel,

and to the rigging, sails, and spars, and will see that the stoppers

are properly applied, and damages repaired as speedily as possible.

In vessels where there is no Signal Officer, the Master, in action or

general exercise, may be directed to perform the duties of Signal

Officer.

118. The Boatswain being the assistant of the Master, is to see that

the rigging, especially forward, is kept clear, and that all damages

are promptly reported and repaired. In the absence of the Master, all

the above preparations will be at once made by the Boatswain, and

reported to the Executive Officer by him.

ENGINEER’S DIVISION.

119. The Chief Engineer will see all proper preparations made for

repairing damages to the engine and its dependencies, and will have

the apparatus for extinguishing fire ready for immediate use. As soon

as these preparations are fully made, and his men mustered, he will

report his division ready to the Executive Officer. He will also

report such damages as may be received in action, and what assistance

is required to repair them, and he will have charge of the

preparations made for extinguishing fires below.

POWDER DIVISION.

120. The Officer commanding this division, when called to quarters for

general exercise or action, will receive from the Captain the keys of

the magazines and shell-rooms, and of their respective water-cocks,

and will deliver them to the persons in charge, who are not to open

them without his special order.

121. He will have the fire-screens let down, and the light-rooms and

the deck under his charge lighted.

[29]122. He will see that the shot and shell whips are in place and in

working order, and that shot-troughs are placed for conveying shot

where required; that the Gunner and his Mates at the magazine hatches

and scuttles, and the persons stationed at the shell-room scuttles,

are ready to open them when the order is given.

123. That all the precautions mentioned in the duties of Gunner and

Carpenter have been taken against fire, namely: that the division-tubs

are filled with water, and that wet swabs are placed by them, and

under all the lower scuttles through which passing-boxes are returned;

that a fire-tub is placed at the bottom of each chute for the return

of empty boxes; that it is nearly filled with water, and has its wire

grating shipped; that a proper supply of fresh water is provided for

the use of the men; that the hatchways of the decks next above that on

which the Powder Division is stationed are properly covered; that the

air-ports are closed and secured; and that the hose is screwed to the

force-pumps and ready for use.

124. He is to see that the means which are provided for lowering the

wounded are ready and properly fitted, and that the wounded, when

lowered down, are conveyed to the part of the vessel set apart for the

Surgeon’s Division, by the persons detailed for that purpose.

125. He will also see that all obstructions to the safe and rapid

passage of powder, shot, and shells are removed; and when every

preparation for action has been made in his division, will report it

ready to the Executive Officer.

126. When the order is given from the Captain to open the magazines,

shell-rooms, and scuttles, he will direct the Gunner and Gunner’s Mate

to repair to their respective scuttles, put on their magazine dresses

and shoes, divest themselves of every article of metal, and see that

the men stationed with them do the same; they are also to see that wet

swabs and cans of fresh water are provided.

127. The magazines being opened, the lids of the tanks are not to be

unscrewed until orders are given to that effect. Then the Gunner and

his Mate, and their assistants in their respective magazines, will

open as many, and no more, tanks than are necessary to supply charges

of the kind ordered, which they will pass up to the men stationed on

the deck above to receive them. These men will be particularly careful

to observe the orders transmitted from time to time, designating the

kind of charges required at the guns.

128. While at general quarters he will see that the men preserve their

proper stations in silence, order, and coolness; and he will give

particular attention to the sufficient and correct supply of powder

and projectiles to the various divisions, and take care that in time

of action, or of exercise with [30]powder, the passing-boxes, after being

once taken out of the magazine, are not passed into it again, or even

inside of the screen, during the whole of such action or exercise.

These duties are of the highest importance.

129. In exercise where no powder is used, he will see that such

substitutes for the various charges as the Captain may direct are

passed up in their proper boxes, so that the number of rounds and the

kind of charge, whether “distant,” “ordinary,” or “near,” may be

ascertained, and compared with those ordered. Should any defect or

deficiency in the arrangement for giving a full supply to the guns be

discovered, it is to be reported immediately to the Captain, in order

that a remedy may be applied as speedily as possible, by additional

men or other proper means.

130. The Carpenter will see that the hatches on the deck next above

the berth-deck or orlop are properly covered with gratings and

tarpaulins, and that the air-ports are closed and secured.

131. He will then cause all the pumps to be rigged, namely, the main

pumps, for freeing the ship in case of leaks, and the force and

channel pumps. He will have the engine also rigged and filled to

supply water for extinguishing fire.

132. He will attend particularly to the preparations for stopping

shot-holes, and see that all the articles enumerated in his general

duties (Article 59) are distributed among his mates and crew.

133. He will, when directed, cause the cabin and other bulkheads to be

taken down, and every other obstruction removed which comes within his

department, that may interfere with the working of the guns or the

passage of ammunition; and having performed this service, will report

to that effect to the Officers of the Divisions in which such

obstructions existed.

134. When these preparations are completed, he will see that the men

under his direction are in their proper stations, and, when all their

preparatory duties have been performed, will so report to the

Executive Officer, and to the Officer commanding the Powder Division

what relates to that division.

135. During an action the Carpenter will attend the pumps, sound the

well frequently, and, should he discover indications of serious injury

below the water-line, will immediately make them known personally,

either to the Captain or to the Executive Officer, and to them only.

136. During an action, such of the Carpenter’s crew as are stationed

in the wings, or on the orlop, in line-of-battle ships, or on the

berth-deck in other vessels, will be constantly on the look-out for

shot-holes.

When a shot enters they are to make its position known by reference to

the numbers of the ports under or near which the hole is found, and

its [31]distance below or above the water-line, as shown by the interior

line corresponding to it, already described in the general duties of

the Carpenter (Article 60); and are also to apply promptly such remedy

themselves as may be in their power.

137. The Master-at-arms, assisted by the Ship’s Corporals, will see

the galley fire and all unauthorized lights put out; that the lamps

are in their places, properly trimmed and lighted; and that the lenses

and reflectors are cleaned and polished.

After the magazines have been swept, closed, and secured, and the

retreat has been beaten, the Master-at-arms will see that the lights

in the light-rooms are extinguished, and apply to the Executive

Officer for permission to renew the usual lights and fires.

SURGEON’S DIVISION.

138. The Surgeon or senior Medical Officer will see that all necessary

preparations are made for the reception and treatment of the wounded,

in the part of the ship which may have been set apart by the Captain

for that purpose, and report to the Executive Officer when such

preparations are completed.

139. He will cause a sufficient number of tourniquets, or temporary

substitutes for them, to be distributed to such men of the different

divisions, and in each top, as may be appointed to receive them; and

he will take care that the persons in his division, and such others as

the Captain may direct, are instructed in the use of tourniquets, to

prevent, as far as possible, any dangerous loss of blood before the

Surgeon or his Assistants can attend to wounded men.

OFFICERS COMMANDING DIVISIONS OF GUNS.

140. Each Officer Commanding a Division of Guns is to see that all

persons belonging to it are present; that all the prescribed

arrangements are duly and promptly made; that every article designated

for use in the division is in order and in place; that the decks are

wet and well sanded; that the hand-swabs at the guns are wet; and that

any small arms that may be distributed among the men of his division

are properly loaded at the time directed by the Captain.

141. In action he will cause the wounded of his division to be

promptly and properly conveyed to the Surgeon, but will see that no

man leaves his quarters on pretence of assisting the wounded. Four

men, “aids to wounded”, should be attached to each Division of Guns,

so as not to take men from guns for that purpose.

[32]142. On the lower deck of line-of-battle ships, or the main deck of

frigates and spar-deck of single-deck vessels, he will see the

hatchways in the range of his division properly covered by the

Carpenter’s crew, assisted by the handspikemen or compressor-men of

the nearest guns, and the scuttles and whips duly prepared for passing

powder, shot, and shells.

143. He will be particularly careful to prevent the men from loading

the guns improperly, or otherwise than may be specially ordered, and

will prevent any unnecessary noise.

144. He will see that the guns are very carefully pointed and properly

aimed; that there is no firing until correct sight can be obtained, as

random firing is not only a waste of ammunition, but it encourages an

enemy, when he sees shot and shell falling harmlessly about and beyond

him.

He will carefully impress upon the Captains of guns that there is no

excuse for several successive bad shots, as observation of the first

or second will surely indicate an erroneous estimate of distance, and

afford means of correcting it. Accuracy of fire is to be encouraged

rather than rapidity.

It is essential to rapidity and accuracy of fire, particularly on

covered decks, that the Division Officers shall keep the Gun Captains

constantly advised of the position and distance of the object.

145. He will also take care to prevent confusion at the

powder-scuttles in the range of his division, and that all orders

which require to be repeated are duly passed. In case of accident to

the Powder-passers, he will promptly supply their places by such men

as can be best spared from his division.

146. He will take care that each gun in his division is provided with

all the “Equipments and Implements” prescribed for its use; and that

the “spare” articles which may be required in his division in action

are in place.—(Article 148.)

147. He will report to the Executive Officer when all preparations

have been made for action; and also after action and exercise, when

the guns have been properly secured, and the stores and implements

belonging to his division have been returned to their places.

EQUIPMENTS AND IMPLEMENTS.

148. Those for broadside-guns, whether mounted on two or four truck

carriages, or on slides, are to be as follows, viz.:

| Articles for each Gun. | Where they are to be put when the Gun is Secured. |

| Carriage complete, with bed and quoin, or elevating screw | At its port. |

| Breeching with shackle-bolts and pins | At the gun. |

| Compressors and levers, pivot-bolt and housing-chock, for Friction Carriages | At the gun. |

| Two side-tackles | Hooked to the securing-bolts on each side of the port and to the carriage. |

| One train-tackle | Hooked to the securing-bolts in the side, with the parts of the fall round the breech of the gun. |

| Two handspikes [1] | Resting on the bed-bolt, in-board ends secured by beckets. |

| One tompion with lanyard and wad | In the muzzle of the gun. |

| One sponge and cap [2] | On the beam or carling over the right side of the gun (on movable brackets). |

| One rammer [2] | On the beam or carling over the left side of the gun (on movable brackets). |

| One lock with string and vent-plug complete | In place on the gun. |

| One breech-sight with cover | In place on the gun. |

| One reinforce-sight with cover | In place on the gun. |

| One priming-wire and one boring-bit, with beckets for the wrist | Inside of the brackets of the carriage, near the breech. |

| One fire-bucket with lanyard | On gun-decks, close to the side, near the beam over the gun; on spar-decks, round the capstan and the boats forward. |

| One bucket of prepared grease or oil for rifle cannon | On the breast-piece. |

| One battle-lantern, with candle or lamp trimmed and primed, but provided for gun-decks only; none for spar-decks |

In the fire-buckets. The candle in supply box. |

| Battle-axes (as prescribed according to the number of men at gun).—See Art. 101 |

Inside of the brackets. |

| One hand-swab | On the breast-piece of the carriage. |

| One deck-bucket and large swab | To be kept in the hold until wanted. |

| Two chocking-quoins for truck-carriages | When not in use, between the brackets and the bed. |

| Two lanyards for each half port | In place. |

| Lanyards, chain pendents, runners and tackles for tricing up, and bars and keys for securing lower deck ports |

In place. |

| Ten shot for shot-guns | In racks round hatches nearest the gun. |

| For shell-guns, one shell in its box | Between the trucks on the left side of the gun. |

| Ten selvagee wads for shot and shell guns | On the breast-piece of the carriage, strung on a pin. |

| Two housing-chocks for lower deck guns | Placed before the front trucks when the gun is run in for housing. |

[1] Marsilly carriages require a roller handspike each.

[2] The rammers and sponges belonging to the broadside-guns

of spar-deck divisions of all ships having topgallant forecastles, or

other light decks, may be kept under the forecastle or light deck when

not in use. In ships not provided with these decks they are to be kept

at the guns inside the brackets; or, if that cannot be done, triced up

overhead on the next deck below.

[34]149. He will also assure himself that the following articles, which

may be required, are in readiness in his division, and prepared for

use, namely: One rattle for calling Boarders; one division-tub for

fresh water; one spare bed and quoin for carriages requiring them; two

spare gun-trucks; four spare handspikes; one worm; one scraper; one

bristle sponge for cleaning guns; two spare breechings; four swabs,

and, if any of the guns be on slides, a spare pivot-bolt. Of these

articles the worm, scraper, sponge, and spare breechings[1] are to be

becketed up between the beams and carlings on the gun-decks as far as

practicable, and those which cannot be so placed will be kept at hand

in the storeroom or other convenient place. A ladle is supplied for

each calibre on board, and will be kept ready in such place as may be

designated by the Executive Officer.

The above allowance of articles designated as “spare,” including worm,

scraper, sponge, and swabs, is upon the supposition that each division

is composed of five guns and their opposites. In case the number of

guns should be either more or less, the articles will be increased or

diminished proportionally to the nearest whole number.

150. He will take care that the Quarter Gunners of his division keep

the two division-boxes marked “supply” and “reserve” constantly

provided with the following articles, all in good order, viz.:

The “Supply” box with a waist-belt for each Boarder, Pikeman, Fireman,

Sail-trimmer, and Pumpman; a primed candle for each battle-lantern; a

thumbstall and vent-guard for the 1st and 2d Captains of each gun. The

belts of Boarders to be furnished with a frog for a pistol, with its

cartridges and percussion-caps; those of 1st and 2d Captains of guns

with a box containing fifty primers fitted to slip on the waist-belt.

Those for Firemen, Sail-trimmers, and Pumpmen to have each a frog for

the battle-axe.

The “Reserve” box with one drill-brace; three vent-drills; one

vent-punch; two gun-locks and strings complete; a flask of

priming-powder; two boring-bits; three priming-wires; eight

thumbstalls; four boxes of percussion-primers; one box of

friction-primers; one spare lock-string for each gun, and one

fuze-wrench; a shackle-punch and pin, and some rags for wiping. These

boxes are to be placed by the Quarter Gunners in their respective

divisions, near the mast, and on the opposite side to that engaged.

In vessels of the class of Frigates and upward, these boxes are to be,

on covered decks, kept in their several divisions and secured

overhead.

On spar-decks they are to be kept under the break of the poop and the

topgallant forecastle, and, in vessels having neither poop nor

topgallant forecastle, between the beams on the berth-deck. They will

be kept under lock and key.

[35]151. He will see that such men of the divisions, and others who are

appointed for the purpose, obtain the requisite number of tourniquets,

and distribute them to the men selected to use them. (See Article

139.)

BROADSIDE GUNS.

STATIONS AND GUN-NUMBERS.

152. The following are to be the gun-numbers and stations for a gun’s

crew composed of sixteen Men and a Powderman, when working

broadside-guns on lower decks; on other decks 15 and 16 are 3d and 4th

Side-Tacklemen.

| Left Side. | Gun-Nos. | Right Side. | |

| First Loader. | 3 | 4 | First Sponger. |

| Second Loader. | 5 | 6 | Second Sponger. |

| First Shellman. | 7 | 8 | Second Shellman. |

| First Handspikeman. | 9 | 10 | Second Handspikeman. |

| First Side-Tackleman. | 13 | 14 | Second Side-Tackleman. |

| First Port-Tackleman. | 15 | 16 | Second Port-Tackleman. |